What’s a softgel capsule hardness tester? Soft gelatin capsules need to undergo elasticity testing before packaging. This is where the tester is required, and not any ordinary tester.

The manufacturers of the capsules need a reliablesoftgel capsule hardness testerto ensure that their products have passed the set industry-standard quality before they release the products to the consuming public.

The result will indicate whether or not the capsule has the go-signal to be packed. This way, repeated failure during packaging, which could mean additional costs to the manufacturer, can be prevented.

Gelomat aims to obtain the highest quality standards in testing gelatin capsules

More about Soft Gel Capsules

There are rules set regarding the use of agelatine hardness testerin capsule products. Typically, the number of tests required depends on the capsules’ unit dose. However, it offers many other benefits that this article will look into.

But first, here’s what you need to know about soft gel capsules. These products are prevalently used in medicines, mineral supplements, and vitamins. The capsule or microcapsules are packed with active ingredients inside to protect the product from a variety of factors.

These active ingredients are released by diffusion, melting, dissolution, or rupture once a person places the capsule into their mouth. How slow or fast the active ingredients will be released depends on the capsule wall’s strength.

Soft gel capsules, also called gel caps or gelatin capsules, are made from animal bone and skin collagen manufactured to make gelatin. There are also vegetarian or vegetable capsules made of cellulose, which use HPMC or hydroxypropyl methylcellulose as the main ingredient. However, it is more cost-efficient to manufacture gel caps, which is why it is more extensively used than the other type.

There are two kinds of gelatin capsules – soft shell and hard shell.

- Soft shell capsules have oils or use active ingredients suspended or dissolved in oil.

- Hard shell capsules have miniature pellets or dry, powdered ingredients. They are made in two halves: One of the halves contains the medicine, and the other half has a bigger diameter, and is used as a cap to seal the capsule.

All about the Gelomat Capsule Hardness Tester

Gelomat is a device used to test capsule hardness automatically. It works for both soft get and regular capsules. It is capable of performing the hardness test on edible gelatin, plasticine, gelatin capsules, and other materials. It comes with a standard testing head, but other accessories can be added to upgrade the device and boost its efficiency.

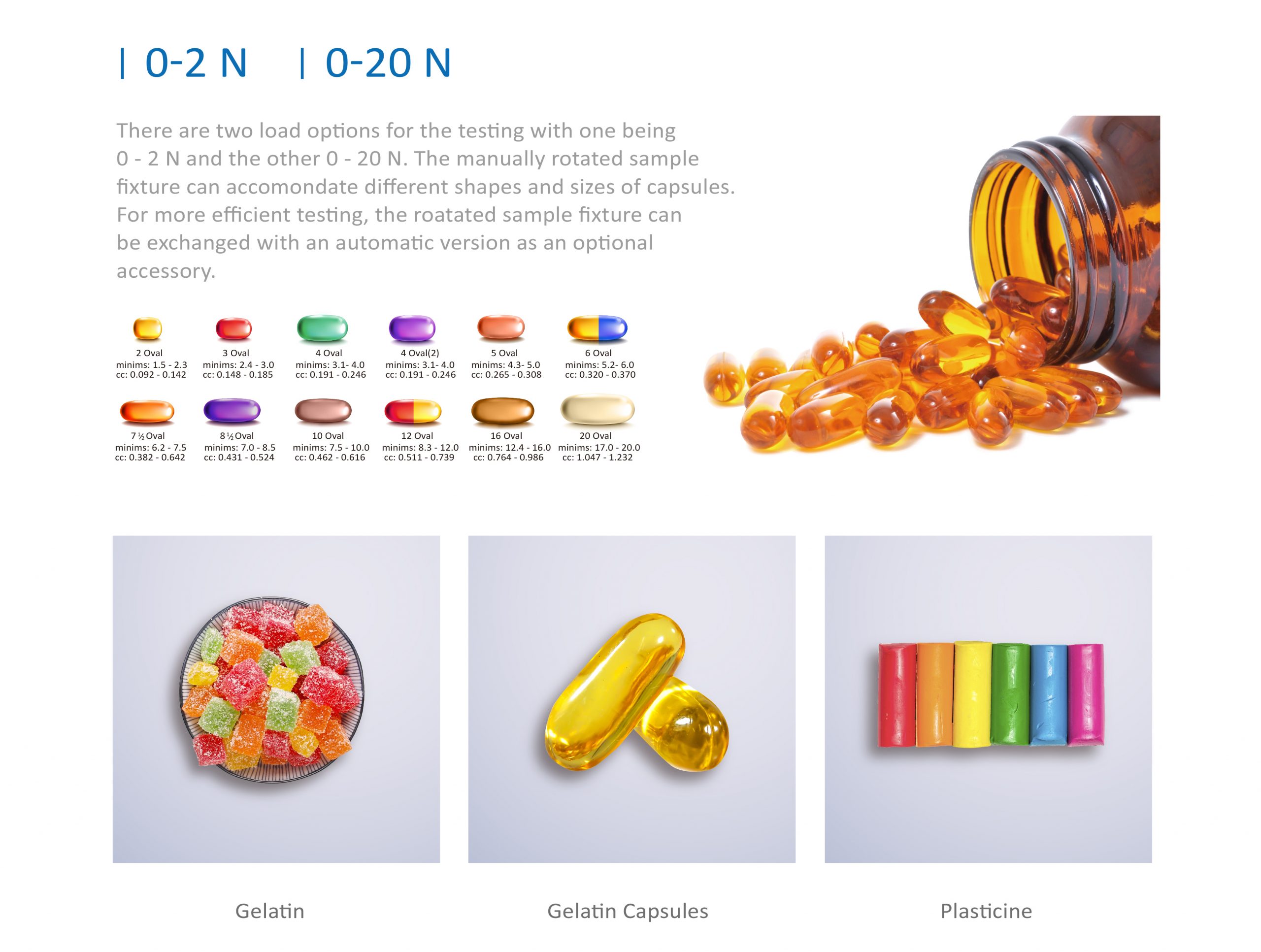

Gelomat aims to obtain the highest quality standards in testing gelatin capsules. It is developed using the latest R&D technology and a state-of-the-art system. The device can be equipped with testing heads that vary in their load capacity: 0-2N and 0-20N. The operator can choose from the heads and interchange them as needed by the requirements.

Top Benefits of a Reliable Softgel Capsule Hardness Tester

1. Non-destructive solution

Gelomat provides a non-destructive solution for testing the hardness of soft gel capsules. Aside from soft gel capsules and gelatin, it can also measure the resistance and hardness of agars, paintball, play dough, and more. The digital measuring systems and the device’s unique design ensure the most reliable and highest level of measuring precision.

Aside from using the standard measuring head from 0-2N or 0-20N, the operator can opt to attach Centrofix or Rotofix. Centrofix is a sample fixture that is operated manually. Rotofix is a positioning device that operates automatically. The user can perform functions with the help of the software, including creating batch folders, viewing histograms, storing data, analyzing the results, and more.

Why all the fuss in testing soft gel capsules? The encapsulating process is meticulous, but it focuses on the form. It ensures the capsule is formed and can hold the filling. Once the capsules have undergone all necessary steps to attain their final form, the testing is done.

Here’s a look at the steps on how to make soft gel capsules:

- A 24-inch in diameter stainless steel drum slowly revolves as the warm liquid gelatin is poured.

- The drum is exposed to the compressor’s flow rate of 400 cubic feet per minute with air temperature up to 590F at 20 percent RH.

- As the drum continues to revolve, the gelatin is congealed with the cool, dry air until an elastic and tacky band rolls over the other end.

- The thin band is what forms the capsules. The process is done automatically.

- The capsules are filled with the manufacturer’s products, such as vitamins, medicine, supplements, and more.

- The filled capsules are sealed and dropped into a tray.

- The filled capsules are still moist and soft, so they are transferred to chambers or drying drums.

Drying time varies on many factors, including the time needed to remove the moisture, the number of capsules, and the size of the capsules.

This is how meticulous it is to form the soft gel capsules. The temperature of the air that the drum gets exposed to during the pouring process is crucial since it can cause the gels to become too brittle or set too fast. Both these results can stop production and repeat the process from the start.

When the air velocity is too high, the thickness or thinness of the gel capsules won’t be consistent. On the other hand, when it is too low, and the humidity and air temperature are too high, the gelatin will find it hard to solidify.

The temperature of the environment needs to be continuously controlled during drying time. The ideal humidity level is at 20 grains per pound of air and a dew point of 25° F.

When the capsules have completely dried, they are tested using a softgel capsule hardness tester, such as Gelomat. Even then, the number of capsules that will eventually be sold to the market will depend on the test results. This ensures that the preserved inventory is of value and won’t compromise the name of the manufacturer.

Why is it important for the device to be highly reproducible? The capsules are tested in batches, and each one in the batch must show similar characteristics and hardness to the rest.

2. The tester was built for durability and accuracy

This gelatine hardness tester was developed with the highest standard accuracy available for a German-manufactured device. It is also highly reproducible.

Why is it important for the device to be highly reproducible? The capsules are tested in batches, and each one in the batch must show similar characteristics and hardness to the rest.

You wouldn’t want the consumer to observe the differences and conclude that the softer ones are expired, or they were given inauthentic items. Only when the capsules are highly replicated can the highest degree of reliability be attained.

In science, reproducibility is the final and third phase of precision testing. To obtain stability, a marker system is selected, depending on the product being tested. In testing gelatin capsules, the dry plasticizer is the suitable weight ratio.

The ratio of dry gelatin to water is 1:1, and the dry gelatin equals 0.4-0.6:1.0. When the weight ratio obtained is 1.8:1, this means that the shell is soft. The weight ratio between the plasticizer and gelatin needs to be 0.3:1.0 for the capsule to be at its hardest form.

3. Suitable for different industries – pharmaceutical industry

A tablet hardness tester is primarily used in the pharmaceutical industry. This laboratory testing determines a tablet’s structural integrity and breaking point. It determines how it changes during handling, packaging, transportation, and storage. The shape determines a tablet’s breaking point.

This kind of tester has been around since the 1930s. But it was only patented in 1953 by Robert Albrecht and called the Strong-Cobb tester. At the time, it was utilized as an air pump.

The problem with the older models of the testers was inconsistency in the results. This is what the newer models, such as the Gelomat, have surpassed.

This is made possible by including the following features in this well-known device:

- Full integration of automatic measuring process

- Hysteresis function

- Gives a high rate of testing efficiency and the highest level of accuracy

- Customized holding fixtures

- Convenient and fast data transfer through a USB port

- User-friendly system designed to meet repeatability and the highest standards of accuracy

- Auto-correction feature

- Digital display shows when values obtained are below or above the limit value

- The digital display unit is capable of various functions, including measuring time and range

4. Suitable for different industries – paintball industry

What’s the use of a hardness tester in the paintball industry? Similar to what needs to be obtained in capsules, paintballs also require a repeatable and reliable method of testing ball seizers, barrels, and markers. The testing system needs to ensure accuracy, repeatability, and simplicity.

In this industry, it is crucial to isolate and define the independent and dependent variables that affect the trajectory of a paintball. The accuracy of the ball highly depends on its quality. You can only shoot the ball straight if it is not swelled, seamed, or dimpled – factors that the tester takes note of and gets rid of.

Aside from the ball quality, the barrel’s hardness also determines the internal finish’s longevity. The holes of the barrel also need to have sufficient angle and size. For the filling, many manufacturers use compressed air because they find it more reliable, and offers a higher accuracy rate than CO2.

5. Suitable for different industries – cosmetic industry

There are many products in the cosmetic industry that will benefit from undergoing hardness testing. For one, a cosmetic foundation goes through the test to ensure that it is hard enough when pressed and qualifies the set standards of R&D and quality control. This is typically done using a tester that utilizes software, cable, test stand, and force gauge measurements. The tester has mechanical properties, including the peeling force, compression, and tension.

The hardness tester can also be used to ensure the quality of cosmetic products, including lipstick, brow or lip pen, and wax and cream products. More than the hardness, the industry relies on the results of the texture test of the products. They have to make sure that the cosmetics feel good on the skin before releasing them to the market.

6. Tests materials for tension and compression

When soft gels undergo testing, the capsule’s wall strength is quantified to determine its rupture point. It also determines the weakness of the seal or the film of the gelatine. The testing is done to simulate the factors that might cause the capsule to burst before it reaches the consumer.

Gelomat applies a compressive force to the capsules to gather data on whether or not they have passed quality control. The device tests the wall strength of the capsules, if they are enough to carry the capsule’s form even after being subjected to external forces.

The purpose of the device is to ensure that no leaking capsules get into the hands of consumers. This results in a higher level of confidence of consumers in the manufacturers and an increased rate that they will buy again.

Hardness testing is only among the many tests that products, such as capsules, go through to implement quality control. The same is true for paintballs and cosmetic products. All these items intended to be bought or consumed by consumers have undergone a series of tests before they are packaged and sold.

For soft gel capsules, each batch undergoes batteries of tests to determine that they meet the standards according to how they are advertised and acceptable for consumption.

7. Uses the latest in technology

Unlike the older models, the recently developed hardness testers, such as the German manufactured Gelomat offer integrated value, efficiency, and the latest in patented technology. Gelomat can be used as a meat hardness tester, cream hardness tester, butter hardness tester, and more. This shows how serious manufacturers are in ensuring that their customers get the best products.

Gelomat employs accurate digital measuring systems and unique design to make the process easier to do without sacrificing the results of the tests. Gelatin capsules undergo an automatic measurement for their hardness through a system that can be trusted to obtain optimum repeatability and accuracy.

The Gelomat system is one of the only systems in the world capable of the ultimate flexibility through the development of custom fixtures and anvils to meet clients unique testing requirements. This makes the Gelomat system a one-of-a-kind solution package.

8. Making it easier to quantify hardness in tablets

Solid tablets are the most common form of dosage used in pharmaceuticals. The hardness of the tablets comprises the specifications of the product’s quality control and criteria for product development.

The tablet hardness tester needs to obtain quality results from the product, meaning that each tablet is not too soft and not too hard.

When a tablet is too soft, it may lead to early disintegration once taken by the patient. It can happen as a result of weak bonding. Additionally, a tablet that is too soft can break or chip during packaging, coating, and other manufacturing stages.

On the other hand, when the tablet is extremely hard, it can lead to the improper dissolution of proper dosage once a patient takes it. The problem may be rooted in too much bonding potential between excipients and active ingredients.

Testing the tablet’s hardness will quantify if the product is consumable and has passed the highest quality standards. However, it also has to contain all mechanical properties needed for optimized results. The manufacturer needs to see that the product used the right composition of the ingredients, the nature of active ingredients, and the binders used. They have to control these factors while still in production to increase the chances that the final tablets will pass the hardness test.

9. Ensures strict compliance to the latest industry standards

When it comes to gelatin capsules, the finished products need to undergo tests. You may already have heard of terms such as capsule hardness tester orgelatine hardness tester.

The capsules undergo a number of tests to comply with the regulatory requirements and compendial standards. The results of the tests will determine if the batch has passed for its intended usage and marketing.

10. Gain public trust

Why are these tests necessary? These products heavily rely on consumers’ trust. Leaking capsules can have a negative impact on how people view the product and all other products from the same manufacturer.

This is why it is crucial that the defective capsules do not reach the market; hence, the manufacturers use a softgel capsule hardness tester to ensure that all the products they will release in the market won’t compromise their name.

Final Thoughts

Your quality control facility will gain many benefits from using the softgel hardness tester, but you have to rely on the tested and quality devices. This is what Bareiss is known for, the company that has been committed to technology and innovations since it was founded in 1954.

NextGen is a registered distributor for Bareiss. We can supply you with German-manufactured equipment, including the soft gel capsule hardness tester. NextGen can additional provide you with the fruit firmness tester, fully automatic shore and IRHD hardness testing systems, and more.