Soil Mechanics Testing Equipment

Standards

ASTM D3080, BS 1377:7, AASHTO T236, CEN-ISO/TS 17892-10, NF P94-071

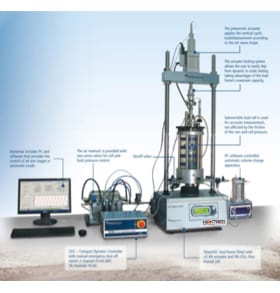

The shear test covers the determination of the consolidated drained shear strength of a soil material in direct shear. The NG-Shear DGEN machine is controlled by a microprocessor system that reads and processes horizontal force and displacement readings, manages the motor and the safety controls through a closed-loop system assuring the following important features:

- Automatic test running

- Test speed closed-loop control

- Large monochromatic graphic display, 240x128 pixels to view data recording in real time

- Different calibration functions (linear and polynomial)

- Language selection

- Travel and cycles programmable by 10 button membrane keyboard with 4 interactive specific icons

- Continuous monitoring and display of horizontal force, vertical and horizontal displacement

- Maximum horizontal displacement (20 mm) controlled by mechanical and optical safety switch

- Different recording modes: linear, exponential (square root), logarithmic, etc.

- High-capacity data memory (up to 1000 lines of data)

- RAM with battery back-up with clock/calendar, operating also when the unit is switched off.

The microprocessor control system, therefore, allows the machine to work as an automatic stand-alone unit: the test measurements (force and displacements) are directly displayed and stored in memory according to pre-set recording modes. The PC is only temporarily required to download the test data via the RS 232 port once the test is completed. The data can be processed by the Direct and residual shear Geo-Analysis templates. See accessories.

The design of the horizontal loading system provides straight-rigid alignment of the loading ram, shear box, and loading measurement system, to increase the stiffness of transmission of the horizontal force along the shearing plane. Excellent quality and high-resistance techno-polymeric material has been adopted for the carriage of the shear box. It offers excellent resistance to corrosion, wear and tear and it is resistant to all chemicals found in a soil specimen. The carriage is lightweight and easy to clean.

The machine is supplied without a load cell, transducer for horizontal and vertical displacement, shear box assembly, and weights. All these items have to be ordered separately. See accessories. The machine can also be fit with a mechanical (analogical) measurement system. Other versions of shear testing machines available: Digital shear testing machine, Automatic shear testing machine, large shear testing machine for 300x300 mm square samples, and bromhead ring shear apparatus.

Main Features

- Microprocessor-controlled drive system

- Large 240x120 pixel display

- Test speed, travel and cycles (up to 9) programmable by the keyboard

- Rapid approach and automatic positioning

- Infinitely variable speed from 0.0001 to 11.00000 mm/min

- Possibility to set different speeds and travel (forward and reverse) in the residual shear test

- Three analog channels: one for load cell, and two for displacement transducers, 130000 points resolution

- Different protocol of data downloading to PC through RS 232 serial port

- Standard load ring and dial gauges also usable for manual recording

Specifications

| NG-Shear DGEN | |

|---|---|

| Speed Range | Adjustable from 0.00001 to 11.00000 mm/min |

| Maximum Shear Force | 5000 N |

| Maximum Vertical Load | 500 N or 5000 N using a 10:1 lever ratio device |

| Horizontal Travel | Pre-set via firmware up to 20 mm |

| Cycles | Up to 9 (forward and reverse) |

| Specimen Sizes | 60 and 100 mm square, 50; 60; 63.5, and 100 mm diameter |

| Overall Dimensions | 95 x 39 x 118 cm |

| Approximate Weight | 120 kg |

FAQs

Yes, the Automatic Shear Testing Machine is fully compliant with the ASTM D3080 standard. This particular standard is important for determining the consolidated drained shear strength of soil materials through direct shear tests. The NG-Shear DGEN is adept at executing these tests, owing to its advanced microprocessor control system. This system not only reads and processes the crucial measurements of horizontal force and displacement but also adeptly manages the motor and safety controls through a closed-loop system.

ASTM D3080 compliance ensures that the Automatic Shear Testing Machine can provide precise, reliable data essential for geotechnical analysis and construction project planning. This capability is particularly helpful for assessing soil stability and predicting potential shifts or failures in earth structures. By adhering to this standard, the NG-Shear DGEN supports civil engineers and geotechnical professionals, offering a solid foundation for designing safe, stable structures that accommodate natural soil behaviors under various load conditions.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Shear Testing Machine is designed to meet the requirements of BS 1377:7, which is a part of the British Standards focusing on methods of testing soils for civil engineering purposes, specifically addressing shear strength tests. The NG-Shear DGEN is equipped with an advanced microprocessor control system that accurately conducts and manages direct shear tests, guaranteeing compliance with this essential standard.

Meeting the BS 1377:7 standard underscores the Automatic Shear Testing Machine's capability to perform reliable and precise shear strength assessments of soil samples. This is crucial for a range of civil engineering projects, from the construction of foundations and retaining structures to the evaluation of landslide risks and the design of earthworks. By adhering to the rigorous protocols outlined in BS 1377:7, the NG-Shear DGEN provides engineers and geotechnical specialists with the necessary data to make informed decisions regarding soil behavior under stress, thereby contributing to the construction of safer and more resilient infrastructure.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automatic Shear Testing Machine, also known as the NG-Shear DGEN, complies with AASHTO T236. This standard is critical for determining the shear strength of soil and rock in highway construction, providing a methodology for the direct shear test of soils under consolidated and drained conditions. Compliance with AASHTO T236 ensures that the Automatic Shear Testing Machine can accurately assess the mechanical properties of soil samples. This is a necessity for the design and analysis of highway foundations, embankments, and other related structures.

The NG-Shear DGEN's ability to adhere to AASHTO T236 standards highlights its utility in the field of transportation engineering. Understanding the shear strength of soils is paramount for ensuring roadway safety and durability. The machine's precision and reliability in conducting these tests make it an invaluable tool for civil engineers and geotechnical professionals involved in highway infrastructure planning, design, and maintenance.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automatic Shear Testing Machine performs tests according to CEN-ISO/TS 17892-10. This technical specification outlines the method for determining soil shear strength using the direct shear test under consolidated and drained conditions. Its compatibility with CEN-ISO/TS 17892-10 ensures that the machine can provide essential data for evaluating soil shear resistance, which is a crucial factor in the design and assessment of geotechnical engineering projects across Europe and internationally.

The NG-Shear DGEN's compliance with this standard demonstrates its capability to support critical analyses required in the construction of stable and safe infrastructure projects, including foundations, slopes, and retaining structures. By conducting tests that comply with CEN-ISO/TS 17892-10, the Automatic Shear Testing Machine aids in the accurate prediction of soil behavior under various loading conditions, offering a reliable basis for engineering decisions and contributing significantly to geotechnical research and practice.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automatic Shear Testing Machine, also known as the NG-Shear DGEN, conforms to the NF P94-071 standard. This French standard specifies procedures for determining soil shear strength through direct shear tests. It emphasizes the importance of accurate soil analysis in construction and geotechnical engineering. The NG-Shear DGEN's compliance with NF P94-071 ensures its capability to accurately evaluate soil samples' shear properties, providing crucial data for the design, analysis, and safety assessment of construction projects in France and in regions that adopt similar testing standards.

The machine's adherence to NF P94-071 highlights its usefulness in many types of geotechnical investigations. This includes the assessment of soil stability on embankments, slopes, and foundation systems. By offering precise and reliable testing results according to this standard, the Automatic Shear Testing Machine supports the engineering community in developing safer, more effective soil management and construction practices.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Shear Testing Machine is specifically designed to conduct tests that cover the determination of the consolidated drained shear strength of soil materials under direct shear. This testing process is crucial for understanding how soil behaves under various conditions of stress and strain, particularly in scenarios where the soil's ability to resist shearing forces is a critical factor in engineering projects' stability and safety.

By evaluating the consolidated drained shear strength, the NG-Shear DGEN provides essential data for geotechnical engineers and construction professionals. This information is vital for the design and analysis of foundations, retaining walls, slopes, and other structures where soil integrity and behavior under load are of primary importance. The Automatic Shear Testing Machine's ability to accurately assess these properties helps in predicting potential soil movement. It also helps in designing structures that can withstand environmental and man-made forces, ensuring their longevity and safety.

Click here to learn more about the product or here to receive a personalized quote.

The automatic test running feature of the Automatic Shear Testing Machine significantly enhances the user experience by streamlining the testing process. This advanced functionality allows the entire test, from consolidation to failure, to be conducted with minimal manual intervention. Once the test parameters have been set, the NG-Shear DGEN automatically controls the execution of the test, including the application of shear force and the measurement of displacement, guaranteeing precise compliance with the predefined conditions.

This feature saves time and increases test accuracy and repeatability by reducing human error. It enables users to focus on analyzing the results rather than managing the operational aspects of the test. This improves efficiency and productivity in the laboratory. The automatic test-running capability is particularly beneficial in busy testing environments or in applications where a high volume of tests is conducted, making the Automatic Shear Testing Machine an indispensable tool for geotechnical, civil engineering, and construction professionals.

Click here to learn more about the product or here to receive a personalized quote.

A closed-loop control feature significantly enhances the operation of the Automatic Shear Testing Machine. This is done by applying precise and consistent control over test speed throughout the testing process. This advanced control system continuously monitors and adjusts the speed to match the pre-set parameters, effectively eliminating variations that could impact the accuracy of the test results.

This level of precision is particularly beneficial for direct shear tests, where strain rate can influence soil's shear strength measurements. By maintaining a constant test speed, the NG-Shear DGEN provides reliable data critical for assessing the consolidated draining shear strength of soil materials.

Furthermore, the closed-loop control system improves the efficiency and reproducibility of tests, making the Automatic Shear Testing Machine an invaluable tool for geotechnical laboratories conducting soil analysis for construction and engineering projects. This feature underscores the machine's capability to meet professional standards, ensuring high-quality testing outcomes.

Click here to learn more about the product or here to receive a personalized quote.

With a large monochromatic graphic display, which measures 240x128 pixels in resolution, on the Automatic Shear Testing Machine, the user experience is greatly enhanced. This is done by providing a clear and intuitive interface for viewing test data in real time. This feature allows operators to monitor shear tests closely, including force and displacement readings as they occur.

There is a good deal of information available on the display that is readily accessible due to its clarity and size. This allows immediate adjustments to be made to the test parameters as a result. Having this level of interaction throughout the testing process is crucial for ensuring accuracy throughout the testing process as well as for making informed decisions based on the observed data throughout the process. Additionally, the display's user-friendly interface simplifies test setup and execution, reducing user error and increasing testing efficiency.

Click here to learn more about the product or here to receive a personalized quote.

What advantages do the different calibration functions offer in the Automatic Shear Testing Machine?

The inclusion of different calibration functions, such as linear and polynomial, in the Automatic Shear Testing Machine (NG-Shear DGEN) offers substantial advantages for precision and versatility in testing. These calibration options allow the machine to be finely tuned to match the specific characteristics of the material being tested, ensuring that the force and displacement measurements are accurate and reliable.

Linear calibration is ideal for materials and test conditions that exhibit a direct relationship between applied force and the resultant displacement. This provides simplicity and ease of use for standard testing scenarios. On the other hand, polynomial calibration can accommodate more complex relationships, where the material response may not be linear across the range of applied forces. This is particularly useful for advanced geotechnical testing where soil behavior under shear stress may exhibit non-linear characteristics due to varying moisture content, particle size distribution, or other factors.

Click here to learn more about the product or here to receive a personalized quote.

The language selection feature on the Automatic Shear Testing Machine provides significant advantages by enhancing its accessibility and usability for operators worldwide. This feature allows users to configure the machine's interface in their preferred language, facilitating a more intuitive and efficient user experience. As a result of removing language barriers, operators can navigate menus, understand instructions, and interpret test results more accurately, therefore reducing the chance that errors will occur during setup and operation.

The availability of multiple languages ensures that the NG-Shear DGEN can be effectively utilized in diverse geographical locations and by multinational teams, promoting wider adoption and standardization of testing protocols across different regions. This inclusivity enhances collaboration and data sharing among researchers and professionals in geotechnical engineering, contributing to the global advancement of soil mechanics research and practice.

Click here to learn more about the product or here to receive a personalized quote.

The programmable 10-button membrane keyboard with 4 interactive specific icons significantly enhances the functionality of the Automatic Shear Testing Machine. It provides a straightforward and efficient means of setting up and adjusting test parameters. This user-friendly interface allows operators to easily program travel distances and cycles for each test, offering precise control over the testing process.

The intuitive layout of the membrane keyboard, combined with the interactive icons, facilitates quick access to commonly used functions and settings, reducing setup time and increasing testing throughput. This design ensures that even complex testing protocols can be easily configured, making the NG-Shear DGEN adaptable to a wide range of testing requirements and standards.

Additionally, tactile feedback from the membrane keyboard offers a reliable and responsive input method, minimizing input errors. This level of interaction enhances the operator's control over the test, guaranteeing that the machine performs as intended and that the test results are accurate and reliable.

Click here to learn more about the product or here to receive a personalized quote.

The feature of continuous monitoring and display of horizontal force, vertical and horizontal displacement on the Automatic Shear Testing Machine significantly enhances its operational efficiency and test results accuracy. This capability allows operators to observe the behavior of the material under test in real time, providing immediate insights into its response to applied forces and movements.

By offering continuous feedback on key parameters, the NG-Shear DGEN ensures that any deviations or anomalies can be quickly identified and addressed, ensuring the integrity of the testing process. This level of monitoring is crucial for understanding the complex interactions between different forces acting on the material, facilitating a comprehensive analysis of its shear strength and deformation characteristics.

Furthermore, the ability to continuously monitor and display these critical metrics supports detailed data analysis and interpretation, aiding in the development of more accurate soil behavior models. This feature is invaluable for geotechnical engineers and researchers who rely on precise data to inform the design and construction of safe and stable structures.

Click here to learn more about the product or here to receive a personalized quote.

The mechanical and optical safety switch is responsible for controlling the maximum horizontal displacement, set at 20 mm, on the Automatic Shear Testing Machine. This safety feature ensures that the machine automatically stops the test if the horizontal displacement exceeds the predefined limit, thereby preventing potential damage to the machine and the test specimen. The incorporation of both mechanical and optical components in the safety switch provides a dual layer of protection, offering precise monitoring and immediate response to displacement limits during testing.

This functionality is particularly helpful during shear strength tests, where exceeding the intended displacement could compromise the accuracy of the test results or cause undue stress on the machine's components. By maintaining the displacement within safe operational limits, the NG-Shear DGEN preserves the integrity of the testing process and extends the equipment's lifespan. Additionally, this safety mechanism supports a controlled testing environment, allowing for reliable and consistent data collection essential for geotechnical analysis and research.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Shear Testing Machine, specifically the NG-Shear DGEN model, offers a versatile range of recording modes to accommodate various data analysis needs. Available modes include linear, exponential (which uses square root functions), and logarithmic, among others. These diverse recording modes enable users to tailor the data collection process to the specific characteristics of the material under test and the objectives of the study.

Linear recording is straightforward and suits tests where changes are expected to occur constantly. The exponential mode is ideal for capturing data in tests where changes accelerate over time, and the square root function can help in understanding the rate of such accelerations. The logarithmic recording is useful for tests where initial rapid changes gradually slow down, providing a detailed view of early test stages.

By offering these different models, the NG-Shear DGEN allows for a more nuanced analysis of material behavior, enhancing the understanding of how materials respond under varying conditions of stress and strain. This capability is invaluable in geotechnical engineering and research, where accurately modeling and predicting material performance can significantly impact the design and safety of construction projects and other applications involving soil and geosynthetic materials.

Click here to learn more about the product or here to receive a personalized quote.

The high-capacity data memory, capable of storing up to 1000 lines of data on the Automatic Shear Testing Machine, offers significant advantages for comprehensive data analysis and long-term research projects. This extensive storage capacity allows for the accumulation of detailed test data over multiple runs, enabling users to conduct thorough analyses of material behavior under various conditions without the need to frequently download or clear memory space.

This feature is particularly beneficial for complex studies where multiple variables are investigated, or for sequential testing scenarios where data sets are compared and correlated. The ability to store a large volume of data directly on the NG-Shear DGEN facilitates a more streamlined workflow, as it reduces the dependency on immediate data transfer to external systems for analysis and storage.

Moreover, the high-capacity data memory enhances the machine's utility in educational settings, research institutions, and commercial laboratories by supporting extensive testing programs and enabling the accumulation of a rich data repository for longitudinal studies.

Click here to learn more about the product or here to receive a personalized quote.

The microprocessor control system significantly enhances the functionality of the Automatic Shear Testing Machine by enabling it to operate as an automatic stand-alone unit. This advanced system manages test measurements, including force and displacement, so that they are not only displayed in real time but also stored directly in the machine's memory according to pre-set recording modes. This automation simplifies the testing process, from initiation to completion, without continuous manual oversight.

The direct display and storage of data facilitated by the microprocessor allows for immediate analysis and review of test results, improving efficiency and accuracy in data collection. Users can select from various recording modes, such as linear, exponential, and logarithmic, to match the specific requirements of their testing protocols, providing flexibility in how tests are conducted and data is interpreted.

Additionally, the microprocessor's ability to control the machine independently provides consistency in test execution, minimizing human error and enhancing test outcomes' reliability. This level of precision and automation makes the NG-Shear DGEN an invaluable tool for geotechnical testing, supporting rigorous analysis and research in soil mechanics and material science.

Click here to learn more about the product or here to receive a personalized quote.

The PC provides central data management for the Automatic Shear Testing Machine, particularly in the post-test phase. Although the machine operates as an automatic stand-alone unit capable of displaying and storing test data directly in its memory, the PC is required for the downloading of this data via the RS 232 port upon completion of the test. This setup allows for the efficient transfer of data from the machine to the PC, where it can be further analyzed and processed.

The use of direct and residual shear geo-analysis templates on the PC enhances the ability to interpret and visualize test results, offering a detailed analysis of the shear strength and other relevant properties of the material being tested. This process ensures that the valuable data collected by the NG-Shear DGEN is maximized for in-depth analysis, supporting research and development projects, quality control, and engineering solutions.

This streamlined approach to data management, where the PC is used primarily for downloading and processing data, emphasizes machine efficiency and convenience. By enabling comprehensive data analysis through specialized software and templates, the Automatic Shear Testing Machine contributes greatly to the advancement of geotechnical engineering.

Click here to learn more about the product or here to receive a personalized quote.

How does the horizontal loading system in the Automatic Shear Testing Machine improve test accuracy?

The design of the horizontal loading system in the Automatic Shear Testing Machine, characterized by its straight-rigid alignment of the loading ram, shear box, and loading measurement system, is vital to maximizing test accuracy. This configuration is specifically engineered to increase the stiffness of transmission of horizontal force along the shearing plane, making sure that the applied force is directly and uniformly transmitted to the sample without any deviation or loss of energy.

By maintaining a straight and rigid path for the force application, the NG-Shear DGEN minimizes potential errors and inconsistencies that could arise from mechanical flexure or misalignment. This precision is particularly important in shear strength testing, where accurate measurement of force and displacement is critical for determining material properties under stress.

Furthermore, this design feature guarantees that the results of the shear tests are reliable and reproducible, essential for geotechnical analysis where the shear strength of soils and other materials directly influences the safety and stability of engineering structures.

Click here to learn more about the product or here to receive a personalized quote.

The adoption of high-resistance techno-polymeric material for the shear box carriage in the Automatic Shear Testing Machine brings several notable benefits, enhancing the machine's durability and functionality. This material is specifically chosen for its excellent qualities, including resistance to corrosion, wear and tear, and the ability to withstand all chemicals typically found in soil specimens. These properties ensure the shear box carriage maintains its integrity and performance over extensive use and exposure to potentially harsh testing environments.

The techno-polymeric material's resistance to corrosion and chemical interaction means that the carriage will not degrade or alter in the presence of various soil types, preserving test results' accuracy. Its durability against wear and tear extends the machine's lifespan, reducing the need for frequent replacements and maintenance.

Furthermore, the lightweight nature of the techno-polymeric material makes the carriage easy to handle and clean, simplifying preparation and turnover between tests. This contributes to greater operational efficiency and enhances the user experience by facilitating straightforward maintenance routines.

Click here to learn more about the product or here to receive a personalized quote.

To fully equip the Automatic Shear Testing Machine for operation, several key components must be acquired separately, as the machine is supplied without these essential items. These components include a load cell, which is critical for measuring the force applied during the shear tests; transducers for horizontal and vertical displacement, necessary for accurately tracking the movement of the sample under load; the shear box assembly, which holds the sample in place during testing; and weights, used to apply vertical load to the sample.

The necessity to order these items separately allows users to customize the machine according to specific testing requirements and standards. Choosing the appropriate load cell, transducers, shear box assembly, and weights makes certain that the NG-Shear DGEN can be precisely adapted to the materials being tested and the particular parameters of the test being conducted.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automatic Shear Testing Machine is designed to accommodate a mechanical (analogical) measurement system, in addition to its standard digital measurement capabilities. This option allows for the use of traditional mechanical gauges for recording force and displacement data, providing an alternative to electronic data capture methods.

Equipping the machine with a mechanical measurement system can be beneficial in scenarios where digital data collection may not be necessary or preferred. This is such as in simpler test setups or in educational environments where the demonstration of the fundamental principles of shear testing is the focus. The mechanical system offers a straightforward method of observing and recording test results, which can be particularly useful for visual learning and in situations requiring a hands-on approach to data acquisition.

The flexibility to switch between digital and mechanical measurement systems enhances the NG-Shear DGEN's applicability across a broad range of testing requirements and user preferences. This adaptability ensures that the machine can meet the diverse needs of geotechnical laboratories, research institutions, and educational facilities.

Click here to learn more about the product or here to receive a personalized quote.

In addition to the Automatic Shear Testing Machine, there are several other shear testing machines available to meet diverse testing needs and specifications. These include the Digital Shear Testing Machine, which offers precise digital controls and data acquisition for a wide range of shear testing applications. Another option is the Large Shear Testing Machine, specifically designed to accommodate larger sample sizes up to 300x300 mm square, making it ideal for testing materials that require a broader surface area for accurate analysis.

The Bromhead Ring Shear Apparatus is also available, providing a specialized solution for evaluating soil residual shear strength. This apparatus is particularly useful in advanced geotechnical investigations where understanding the long-term stability of slopes and other soil-structure interactions is critical.

Each shear testing machine is customized to specific testing requirements. It offers a range of capabilities from basic mechanical measurements to advanced digital data processing. This variety ensures that researchers, engineers, and educators can select the most appropriate equipment for their specific testing conditions, whether they are conducting routine quality control assessments, detailed research studies, or educational demonstrations in soil mechanics.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Shear Testing Machine features an infinitely variable speed range from 0.0001 to 11.00000 mm/min, providing exceptional versatility and precision in conducting shear strength tests. This wide speed range allows for detailed control of test conditions, accommodating a wide spectrum of geotechnical testing protocols that require different shear application rates.

The ability to finely adjust speed to such precise levels enables users to replicate various natural and engineered soil conditions accurately, from very slow consolidation processes to faster shear failure scenarios. This flexibility is crucial for understanding how different materials respond to diverse loading rates, which is essential for predicting their behavior in real-world situations.

Furthermore, the flexibility of the system facilitates the execution of specialized tests, such as those assessing the time-dependent behavior of materials or the effects of rapid loading, which are important for evaluating geotechnical structures' performance under different environmental conditions and stressors.

Click here to learn more about the product or here to receive a personalized quote.

The inclusion of three analog channels, each with 130000 points resolution, significantly enhances the testing capabilities of the Automatic Shear Testing Machine by providing high precision in load and displacement measurement. One channel is dedicated to the load cell for accurately capturing the force applied to the sample, while the other two channels are reserved for displacement transducers, measuring both vertical and horizontal movements with exceptional detail.

This high-resolution data acquisition guarantees that even the most subtle changes in load and displacement are detected, offering a comprehensive understanding of the material's behavior under shear stress. The ability to capture data at such a fine resolution is essential for advanced geotechnical testing, where detailed analysis of soil and material properties under different conditions is required to predict their performance in real-world engineering applications. Furthermore, the separate channels for load and displacement allow for simultaneous monitoring and recording of multiple parameters, facilitating a more efficient and thorough analysis of test results.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automatic Shear Testing Machine supports standard load rings and dial gauges for manual test data recording. This feature provides flexibility in how data is collected, allowing users to choose between automated digital data capture and traditional manual recording methods. The compatibility with standard load rings and dial gauges ensures that the machine can be easily integrated into a wide range of testing environments, accommodating both modern and conventional geotechnical laboratory setups.

The option to use manual recording tools like load rings and dial gauges is particularly beneficial in cases where digital data collection may not be required. This is especially true in educational settings where demonstrating shear strength testing principles through hands-on experience is valuable. It also serves as a reliable backup method for data collection, so that testing can continue even in the event of digital system failures.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Shear Testing Machine boasts a maximum shear force capacity of 5000N. This substantial force capability allows the machine to accurately simulate materials' conditions in real-world applications, particularly in geotechnical engineering. The 5000N maximum capacity guarantees that the NG-Shear DGEN can conduct rigorous shear strength tests on a range of soil types and other materials, providing critical data for the assessment of their stability and integrity under shear stress.

The level of shear force capacity that can be applied to construction materials is essentially crucial for evaluating their performance, especially when it comes to determining the safety and feasibility of structures constructed on or using these materials. The ability to apply such a significant amount of force makes the Automatic Shear Testing Machine a valuable tool for those involved in research, development, and quality control processes since it is capable of applying such a large amount of force.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Shear Testing Machine is designed to accommodate a versatile range of specimen sizes, making it suitable for a range of testing requirements. It can test square specimens of 60 and 100 mm, as well as circular specimens with diameters of 50, 60, 63.5, and 100 mm. This flexibility allows users to test different materials under different conditions, providing comprehensive insights into the shear strength and deformation characteristics of soils and other geotechnical materials.

The ability to handle such a diverse range of specimen sizes means that the NG-Shear DGEN can be used for detailed analysis in both research and practical applications. Whether for standard compliance testing, investigative research, or educational purposes, the machine's capacity to test multiple sizes increases its usefulness in geotechnical engineering labs, offering precise and reliable data critical to understanding material behavior and informing engineering decisions.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Shear Testing Machine's overall dimensions are compact, measuring 95 cm in length, 39 cm in width, and 118 cm in height. This design was strategically developed to balance the machine's robust testing capabilities with a footprint that considers laboratory space constraints. The dimensions reflect a thoughtful engineering approach that ensures the machine can be accommodated in different testing environments without extensive space.

Despite its relatively compact size, the NG-Shear DGEN does not compromise on functionality. It is equipped to handle a broad range of tests with different specimen sizes and testing conditions, from standard soil shear tests to more complex geotechnical investigations. The machine's design facilitates easy setup, operation, and maintenance, enhancing the user experience and operational efficiency. This combination of compact design and versatile testing capabilities makes the Automatic Shear Testing Machine an essential tool for laboratories focused on geotechnical analysis and research.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Shear Testing Machine weighs approximately 120 kilograms (kg), equivalent to about 264.6 pounds (lbs). This substantial weight is indicative of its robust construction, utilizing high-quality materials that provide both durability and stability throughout testing procedures. The significant mass of the machine is critical to its overall functionality, anchoring it securely to prevent any unwanted movements or vibrations that could potentially skew test results.

Despite its sturdy build, the NG-Shear DGEN design is thoughtfully considered to balance between its extensive testing capabilities and practical aspects of laboratory usage, such as spatial efficiency and ease of maneuvering within the testing environment. The weight contributes positively to machine performance, enhancing shear strength assessments by maintaining a consistent and reliable testing platform. This blend of stability, reliability, and operational convenience makes the Automatic Shear Testing Machine a valuable tool for conducting advanced geotechnical investigations and material testing.

Click here to learn more about the product or here to receive a personalized quote

Related Products

Moisture Determination Balance - GenMoist

GenMoist is designed to automatically and simultaneously dry and weight a solid sample for the determination of moisture content. The machine provides a continuous direct readout for both the weight and the percentage moisture loss through the entire cycle. It has a build-in timer.

MULTISPEED Digital Automatic Universal Tester for Displacement Controlled Tests

The new MULTISPEED tester is the ideal solution for Road testing laboratory. The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not only the CBR and Marshall tests, but many other applications as for instance Indirect Tensile test, Quick Triaxial tests, Unconfined and Uniaxial soil testing and, in general, all test to be performed under displacement control. The machine can be equipped with analogical or digital load/displacement measurement systems as well as with the specific accessories, to suit either the field or central laboratory requirement.

Dynamic Triaxial Systems 1000 kPa

Dynatriax systems are ideal for commercial and research laboratories for the following applications: Liquefaction potential, Strength degradation due to cyclic loading, Shear modulus and damping ratio, resilient modulus, Effects of blasting in mines and quarries, Effect of ocean waves on costal and off shore structures.

Automatic Triaxial Test Systems

The AUTOTRIAX Automatic triaxial system not only can perform Effective Stress triaxial tests with all the above vantages but is the unique and indispensable apparatus to perform the Stress Path test.

NG-Oedometer - Front Loading Oedometers - Consolidation Test

This test determines the rate and magnitude of consolidation of a soil specimen restrained laterally and subjected to a number of successive increments of vertical loads.

ACE - Automatic Computerized Oedometer

ACE - is the most advanced automatic computerized oedometer for testing soil consolidation that can measure the response of soil specimens.

Shearmatic 300 - Large Shear Testing Machine

The SHEARMATIC 300 automatic machine is ideal for testing geosyntetics and also soil and other materials that contain large particles of up to 20 mm largest dimension. Sample size up to 300 mm square can be tested, with inserts allowing the testing of smaller sample sizes. See accessories.

Resonant Column and Torsional Shear Tester

RESONANT COLUMN combines the features of both resonant column and torsional shear into a single unit including the current driven motor to apply torsional load to sample, a series of transducers with signal conditioning, a cell and back pressure electro-pneumatic control system and a data logger.

Shearmatic - Automatic Shear Testing Machine

This microprocessor based advanced model, is a stand-alone machine, driven by a high-resolution stepper motor with epicyclical reduction gear with reduced backlash. Incorporate a pneumatic closed loop system for the automatic application of the axial pressure by a high performance pressure regulator, with the main advantage of eliminating the manual loading of the dead weights. Excellent and high resistance techno-polymeric material has been adopted for the carriage of the shear box. It offers excellent resistance to corrosion, wear and tear and is resistant to all chemicals found in a soil specimen. The carriage is lightweight and easy to clean.

Laboratory Vane Apparatus

The laboratory vane apparatus is based on an original concept of the Transport and Road Research Laboratory of the United Kingdom. It can be provided with a wide range of vane sizes, although as standard, it is sold with the 12.7 mm square vane and a set of four calibrated springs. The test can be performed directly on the sample or in the sample contained in the sampling tube. In this case the NG-WF1736 Attachment for 38 and 100 mm dia. sampling tubes, should be used. See accessories.