Metal Testing Equipment

The GenCut Series – Precision Metallographic Cutting Equipment offers a range of machines to match your specific cutting requirements. These precision metallography cutters are equipped with the highest level of cutting accuracy and have a user friendly interface for ease of operation. Straight or angular cuts can be performed on a variety of specimens ranging from flat, tubular and irregular sizes. The precision cutting saws are ideal to prepare specimens for hot or cold mounting process for microscopy. Standard and custom vices, spare parts, and a full scope of consumables is readily available in stock.

Products

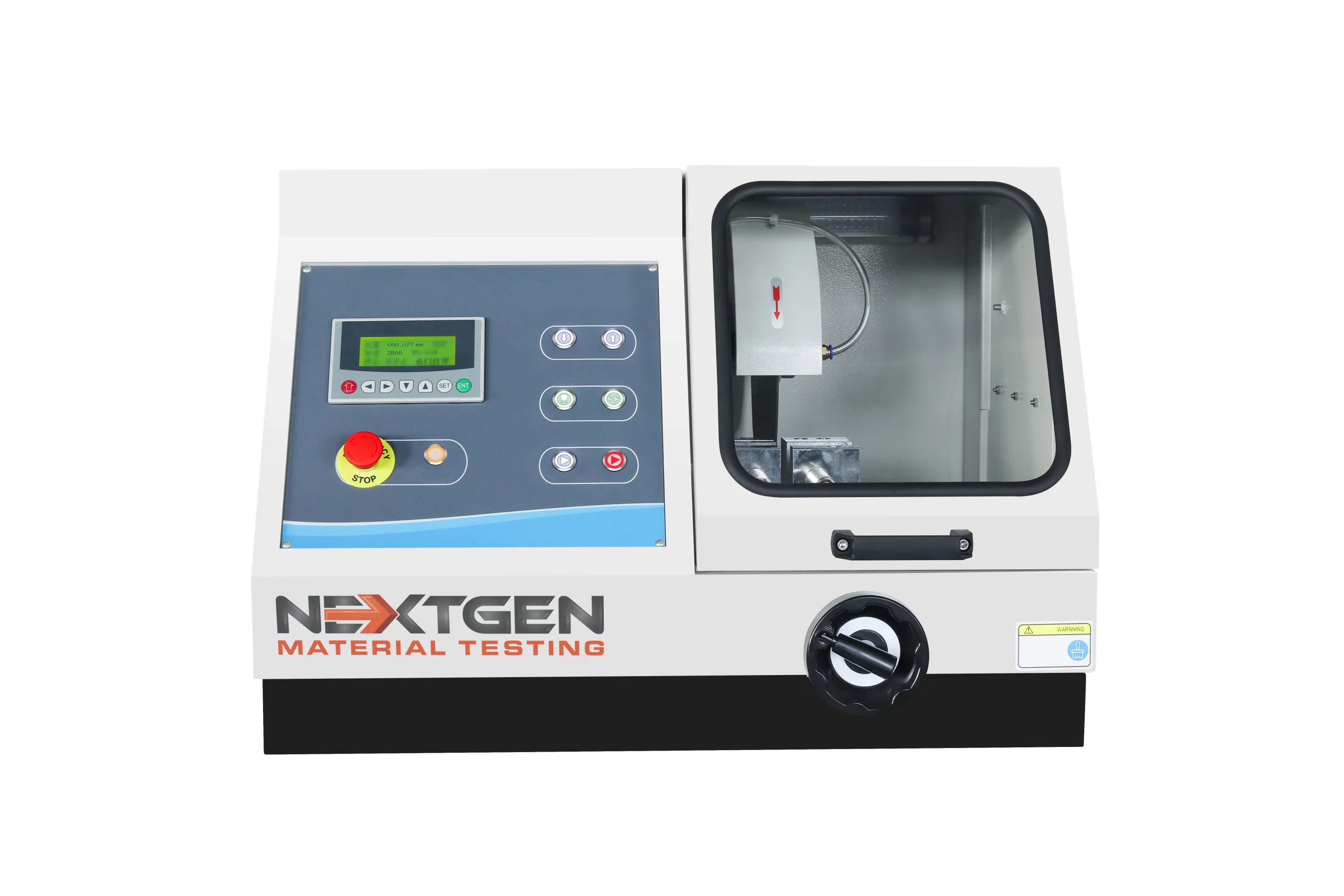

GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

Introducing the GenCut GL100M Manual Cutting Machine, expertly designed for precision metal sample cutting.

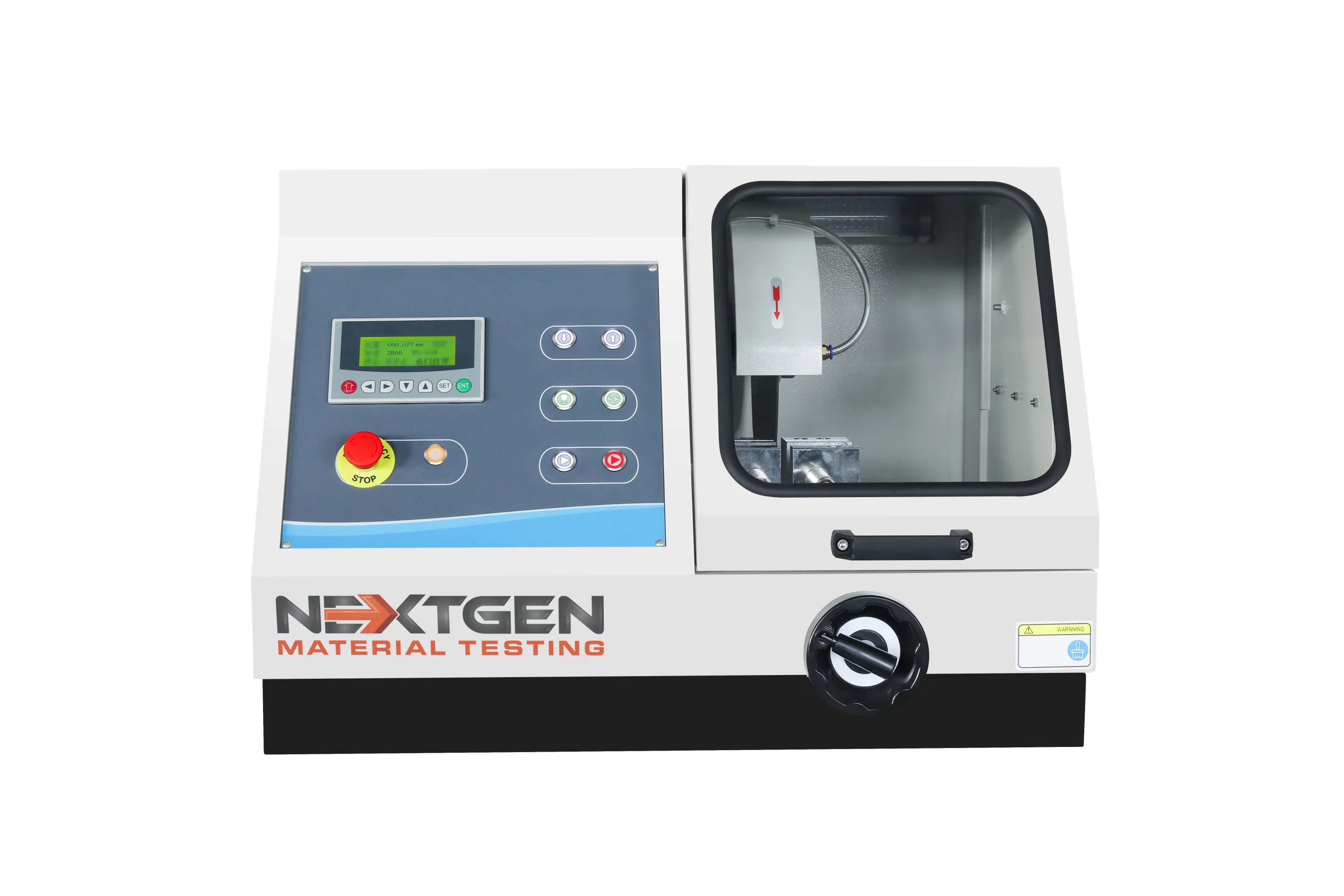

GenCut GL350 – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities

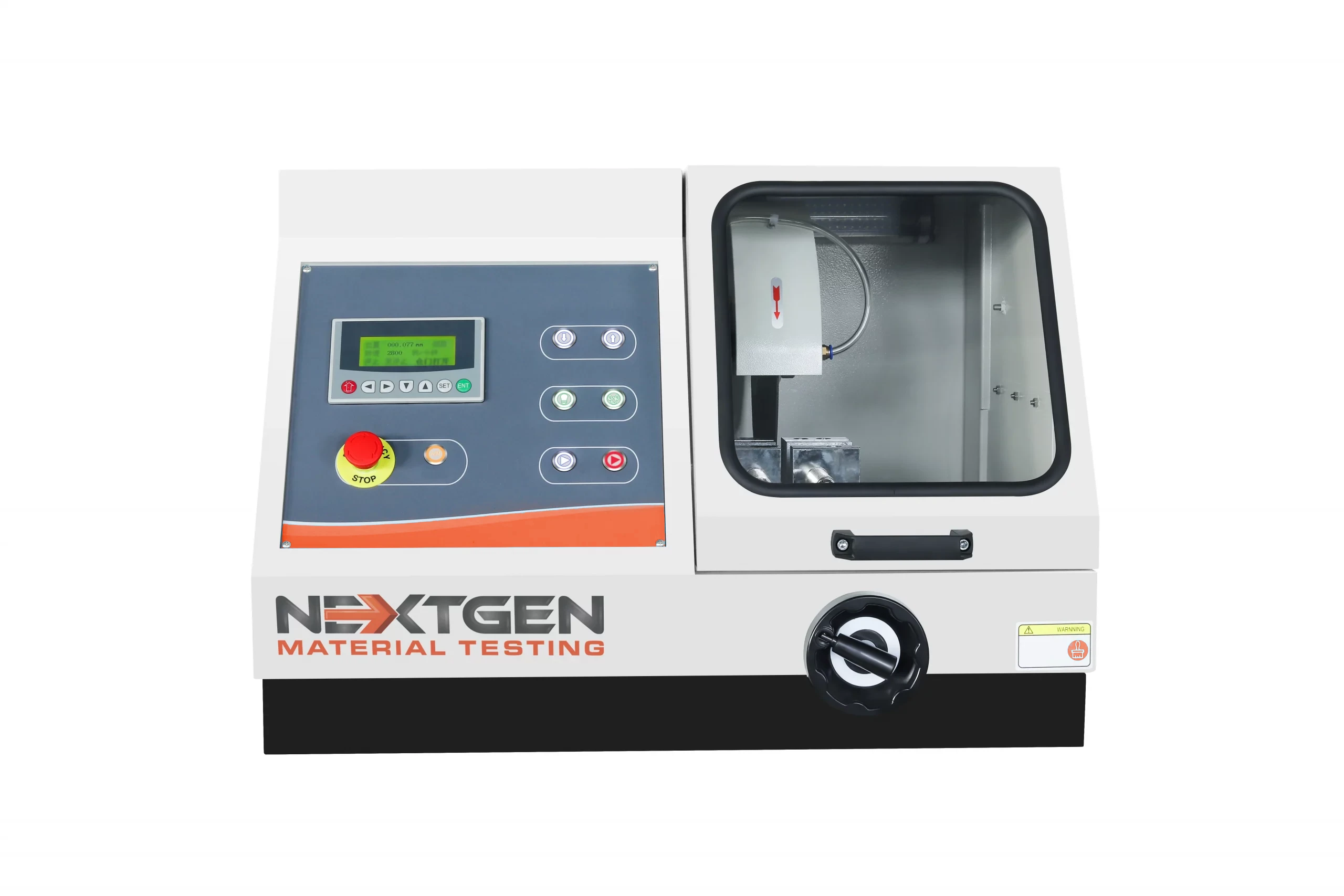

GenCut GL80A – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ80mm

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes.

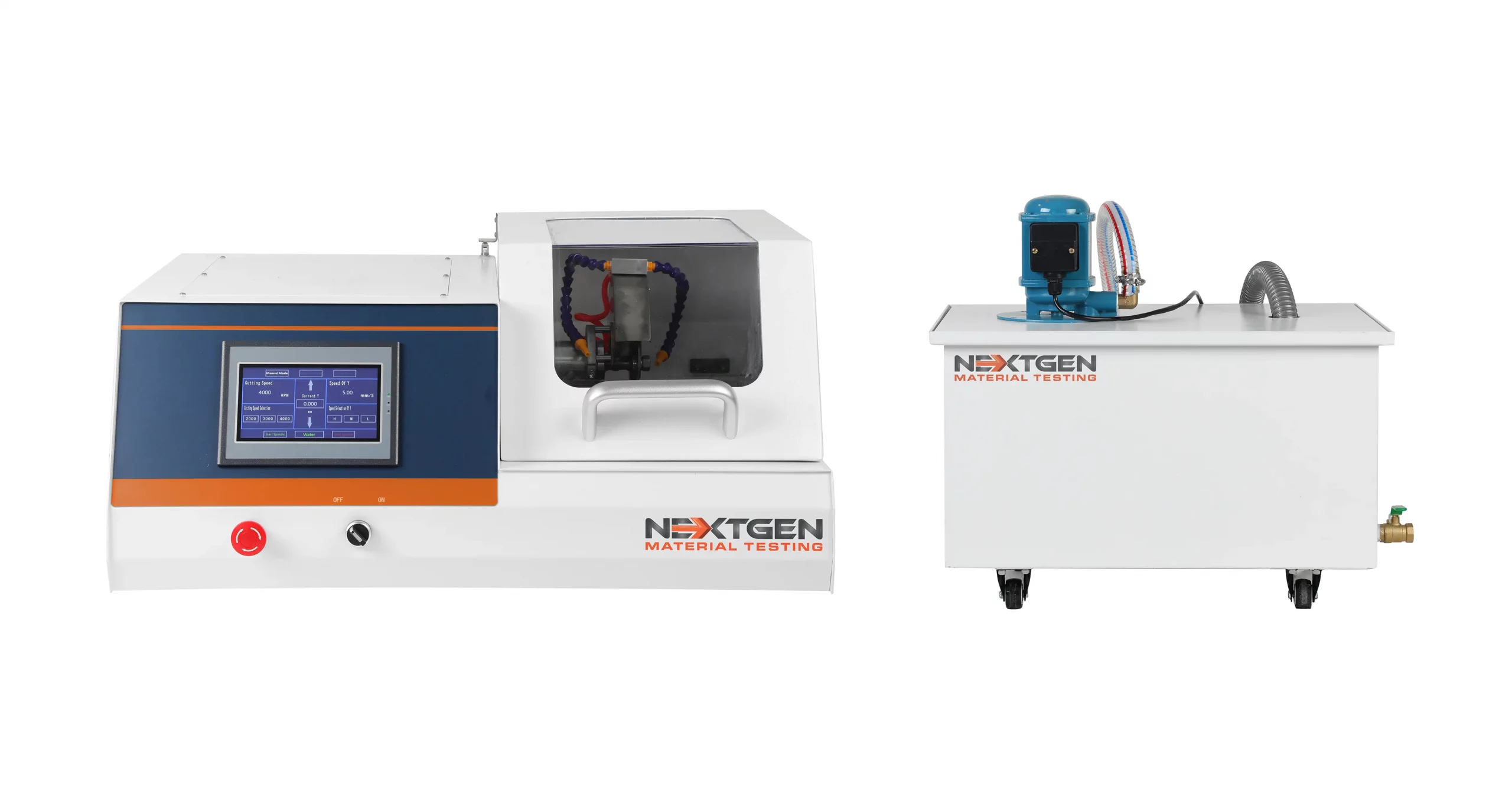

GenCut GL 200E – High Speed Automatic Precision Metallographic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 60mm

GenCut GL 200E precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display parameters.

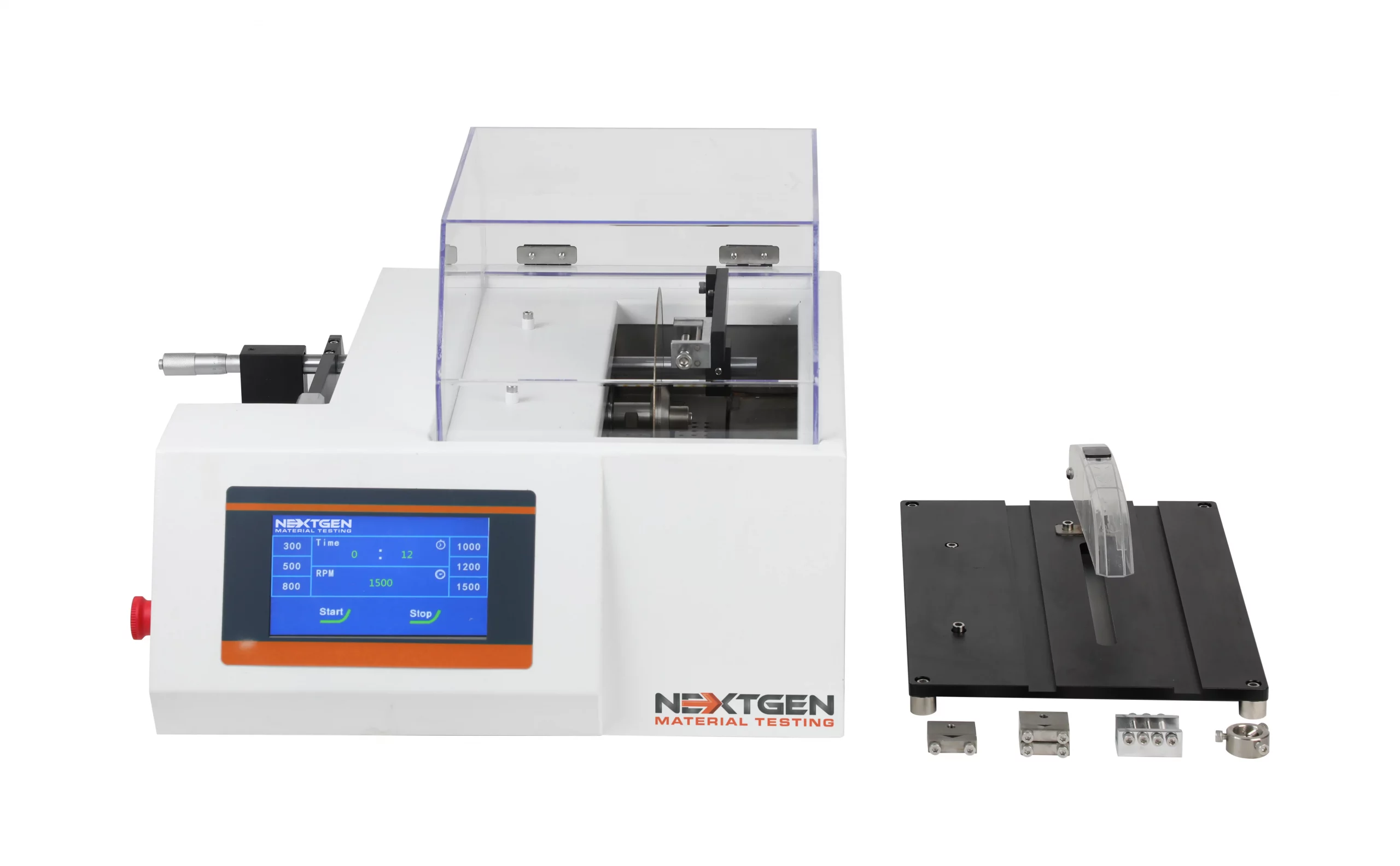

GenCut GL 100E – Low Speed Precision Metallographic Automatic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 25mm

GenCut GL 100E low speed series metallographic precision cutter has variable speed control from 50-1000 rpm.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.