Soil Mechanics Testing Equipment

Standards

ASTM D3080, ASTM D6243, BS 1377:7, EN ISO 12957, ASTM D5321

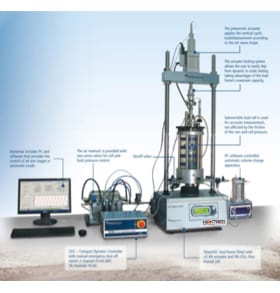

The Shearmatic 300 automatic machine is ideal for testing geosynthetics and also soil and other materials that contain large particles of up to 20 mm largest dimension. Sample sizes up to 300 mm square can be tested, with inserts allowing the testing of smaller sample sizes. See accessories.

Using a large sample is possible to gain a more representative indication of shear strength. Furthermore, the large shear box can be used to obtain the angle of friction between many materials. Particular applications include the construction of earth dams and other embankment work.

The machine includes a 100 kN load cell and linear potentiometric transducers 100 and 50 mm travel with mounting brackets and a shear box.

Main Features

- Ideal for testing Shale, Industrial slag, Brick rubble, Colliery spoils, Geosyntetics

- Sample size up to 300 mm

- 100 kN shear and consolidation force

- Sleeplessly variable speed control from 0 to 11.00000 mm/min

- Automatic hydraulic application of pre-set consolidation steps (up to 50)

- Automatic test management from consolidation to failure: the operator is only requested to remove the clamping screws of the shear box

- The straight connection between shear box, drive unit, and load cell for the axial transmission of the horizontal force along the shearing plane, instead of the classic "swan neck"

- Easy and immediate setup of the test parameters via the large digital graphic display

- Possibility to set different speeds and travel (forward and reverse) in the residual shear tests

- Each single step of axial force can be applied instantaneously or by means of a linear ramp in a pre-set time interval

- Different and independent data recording for consolidation and failure

- Different protocols of data downloading via RS 232 serial port

Specifications

| NG-Shearmatic | |

|---|---|

| Sample Size | Up to 300 mm. Can be reduced to 150 mm using NG-WF2304/1 150 mm sample insert. See accessories. |

| Shear and Vertical Force | 100 kN |

| Speed Range | Sleeplessly variable from o to 11.00000 mm/min |

| Maximum Travel | 75 mm |

| Steps of Consolidation | Up to 50 |

| Data Acquisition | RS232 serial port for use with Direct and residual Geo-Analysis templates (see accessories) |

| Power | 2000 W |

| Overall Dimensions | 147 x 76 x 157 cm |

| Approximate Weight | 800 kg |

FAQs

Yes, the Shearmatic 300 – Large Shear Testing Machine is specifically designed to comply with the ASTM D3080 standard, which outlines the procedures for conducting direct shear tests on soil. This standard is critical for evaluating the shear strength of soil samples. It provides essential data for geotechnical engineering projects such as foundation design, slope stability analysis, and soil-structure interaction assessments.

It is important to note that the Shearmatic 300 is certified to ASTM D3080, which ensures that the device will accurately measure soil shear resistance, providing accurate and reliable results to permit construction and civil engineering professionals to make well-informed decisions. As a result of the sophisticated design and capabilities of the machine, it is able to conduct detailed analyses of soil behavior under different conditions, thereby supporting the development of safer and more efficient engineering solutions throughout the world.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Shearmatic 300 – Large Shear Testing Machine complies with ASTM D6243 standard. This standard specifies test methods for determining geosynthetic strength and deformation under direct shear conditions. The Shearmatic 300's design and functionality are tailored to meet ASTM D6243 requirements, enabling it to accurately evaluate the interaction between different geosynthetic materials and between geosynthetics and soil.

This compliance is particularly important for projects that use geosynthetics for reinforcement, stabilization, or filtration purposes. The ability to perform ASTM D6243 tests means that the Shearmatic 300 can provide critical data on geosynthetic materials' performance in simulating real-world conditions. By offering precise and reliable testing capabilities, the Shearmatic 300 aids in the selection and quality assurance of geosynthetics used in civil engineering, environmental, and geotechnical applications, ensuring that they meet the necessary standards for durability and functionality.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine is designed to meet the rigorous demands of soil and geosynthetic testing, making it well-suited to complying with standards such as BS 1377:7 and EN ISO 12957. BS 1377:7, part of the British Standards for methods of test for soils for civil engineering purposes, focuses on shear strength tests (total stress) and (effective stress), and shear strength tests on soils under consolidated conditions. On the other hand, EN ISO 12957 specifies requirements for determining geosynthetic friction characteristics.

The Shearmatic 300's advanced design and capabilities ensure that it can perform a wide range of shear testing protocols required by these standards, providing accurate and reliable results for soil and geosynthetic materials. Its compliance with such standards underscores its utility in civil engineering, geotechnical, and environmental projects, where understanding materials' mechanical properties is crucial for design and safety considerations. By facilitating tests that adhere to BS 1377:7 and EN ISO 12957, the Shearmatic 300 supports the assessment and verification of material characteristics essential for the successful completion of construction projects.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Shearmatic 300 – Large Shear Testing Machine complies with the ASTM D5321 standard, which outlines the test method for determining geosynthetic interface shear strength. This standard is essential for evaluating the performance of geosynthetic materials when used in conjunction with soil or other geosynthetics in a variety of civil engineering applications, including earth retaining systems, landfill liners, and road construction projects.

The Shearmatic 300's capability to meet ASTM D5321 requirements ensures it can accurately assess shear strength at the interface of geosynthetics and between geosynthetics and soils. This is crucial for the design and assessment of geotechnical and environmental engineering projects. Interface shear strength directly influences the constructed system's stability and integrity. By providing precise and reliable testing results, the Shearmatic 300 aids engineers and designers in making informed decisions regarding material selection and project design, improving the safety and durability of the infrastructure.

Click here to learn more about the product or here to receive a personalized quote.

The main purpose of the Shearmatic 300 – Large Shear Testing Machine is to conduct comprehensive shear strength testing on a wide range of materials, including geosynthetics, soil, and other materials that contain large particles up to 20 mm in size. It is specially designed to assess the shear strength and deformation characteristics of these materials under controlled conditions, providing essential data for geotechnical, environmental, and civil engineering applications.

The Shearmatic 300 is an ideal instrument for evaluating the performance of geosynthetic materials that are used in construction and environmental protection projects, such as landfill liners, retaining walls, and erosion control systems. Since it is capable of testing materials with large particle sizes, it is ideally suited to a number of real-world applications where such conditions are typically encountered. The machine's automated features and compliance with international standards ensure accurate, reliable, and efficient testing processes.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine tests samples up to 300 mm square, making it suitable for a broad range of material testing applications. This large sample size capacity is particularly beneficial for the comprehensive evaluation of geosynthetics, soils, and other materials that require larger specimen sizes to accurately assess their shear strength and deformation characteristics under applied loads.

To accommodate smaller sample sizes, the Shearmatic 300 includes the option of inserting smaller samples into it. These inserts allow for the versatile testing of various sample sizes within the machine's maximum capacity, ensuring that tests can be tailored to specific project requirements or standard protocols. This flexibility enhances the machine's utility across different testing scenarios, from research and development to quality control and compliance testing. By providing the capability to test both large and small samples with precision, the Shearmatic 300 – Large Shear Testing Machine stands out as a comprehensive solution for material testing in geotechnical and civil engineering projects.

Click here to learn more about the product or here to receive a personalized quote.

The use of a large sample size in the Shearmatic 300 – Large Shear Testing Machine offers a more representative indication of the material's shear strength, enhancing the accuracy and reliability of test results. Larger samples encompass a broader range of material characteristics, including variability in particle size, distribution, and overall heterogeneity. These factors are vital in geotechnical and civil engineering projects. This comprehensive approach to testing ensures that the measured shear strength closely reflects the conditions the material would experience in actual use, providing a solid foundation for design and analysis.

Moreover, the large shear box available with the Shearmatic 300 facilitates the determination of the angle of friction between a wide variety of materials. This measurement is essential for understanding how different materials interact under stress, affecting their stability and performance when used together in construction and environmental applications. By accurately determining the friction angle, engineers and designers can make informed decisions regarding material selection and project specifications. The Shearmatic 300's capacity to test large samples and determine critical material properties like the angle of friction underscores its value in advancing material science and engineering practices.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine is particularly useful in earth dam construction and other embankment work. Its ability to test large samples provides accurate data on the shear strength and angle of friction of the materials used in these projects, which are critical for ensuring stability and safety. The machine's testing capabilities enable engineers to assess how soil and other construction materials will behave under pressures exerted by large structures such as dams and embankments.

The information provided by this report is crucial for designing structures that can withstand environmental stresses over time, preventing failures, and ensuring that the construction lasts as long as possible. There is no doubt that the Shearmatic 300 is a valuable tool for civil engineers and construction managers alike due to its precise and reliable testing process that supports the development of effective solutions for managing earthwork construction risks.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine is equipped with several key components that enhance its testing capabilities, including a 100 kN load cell and linear potentiometric transducers with 100 mm and 50 mm travel, complete with mounting brackets. Additionally, it comes with a shear box, which is essential for conducting direct shear tests on a variety of materials.

The 100 kN load cell enables the machine to apply significant force to the test specimen. This makes it suitable for a wide range of materials and testing requirements. The linear potentiometric transducers provide precise displacement measurement during the test, ensuring accurate data collection on the material's response to the applied load. The inclusion of mounting brackets facilitates the secure and proper placement of these transducers, enhancing measurement reliability.

Together, these components ensure that the Shearmatic 300 can perform comprehensive shear strength testing, offering detailed insights into material properties crucial for construction and engineering projects. This setup allows for versatile testing applications, from geotechnical analysis to research and development in material science.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine is ideally suited for testing a diverse range of materials, including Shale, Industrial slag, Brick rubble, Colliery spoils, and Geosynthetics. Its robust design and versatile testing capabilities make it an excellent choice for evaluating the shear strength and deformation characteristics of these materials. These materials are commonly encountered in construction, environmental, and geotechnical engineering projects.

Testing these materials provides crucial data for assessing their suitability and performance in various applications, such as building foundations, earthworks, landfill construction, and erosion control systems. The Shearmatic 300's ability to handle large particles and complex material compositions ensures accurate and representative testing that is essential for designing safe and durable structures. Its application in testing geosynthetics also supports the development and quality assurance of products used for reinforcement, stabilization, and filtration in engineering solutions.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine's capacity to accommodate samples up to 300 mm is significant for conducting comprehensive material testing across a broad spectrum of applications. This capability ensures that larger and more representative samples of materials such as geosynthetics, soil, industrial slag, and construction rubble can be accurately assessed for their shear strength and deformation properties. Testing larger samples is essential for capturing the variability and true behavior of materials under stress, providing insights that are critical for engineering project design and evaluation.

The ability to test up to 300 mm samples is particularly valuable in geotechnical engineering, where understanding materials' mechanical properties is crucial for the stability and safety of structures like earth dams, embankments, and retaining walls. It also plays a vital role in environmental engineering projects, such as landfill construction, where material integrity under varying loads and conditions must be assured.

Click here to learn more about the product or here to receive a personalized quote.

The 100 kN shear and consolidation force capability of the Shearmatic 300 – Large Shear Testing Machine significantly enhances its testing applications, providing the power needed to conduct rigorous shear strength and consolidation tests on a wide range of materials. This high-force capacity enables the machine to apply substantial loads to test specimens, making it ideal for evaluating materials' behavior under conditions that mimic real-world stresses, such as those found in construction and geotechnical engineering projects.

This capability is particularly important for testing materials like shale, industrial slag, brick rubble, and colliery spoils. Understanding the material's resistance to shear forces and its consolidation behavior under load is crucial for determining its suitability for use in construction and environmental applications. Additionally, the 100 kN capacity allows for the effective testing of geosynthetics, assessing their interaction with soils and other materials under significant stress.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine features seamlessly variable speed control ranging from 0 to 11.00000 mm/min, providing exceptional precision in adjusting the test speed to match specific testing requirements. This wide and finely tunable speed range allows for careful shear and consolidation tests, accommodating a diverse array of material testing protocols.

This capability is particularly beneficial for conducting tests that require very slow rates to simulate long-term geological processes or quick rates for assessing material behavior under rapid loading conditions. The precision of speed control means that the Shearmatic 300 can replicate a vast range of real-world situations, from the slow settling of soil layers to the quick shear forces experienced during seismic events.

The ability to adjust speeds so precisely and over such a broad range enhances the machine's versatility, making it suitable for research and quality control in many fields, including geotechnical, civil, and environmental engineering. This feature ensures that the Shearmatic 300 meets the exacting standards of modern material testing, providing accurate, reliable data essential for the design and assessment of construction projects and material performance.

Click here to learn more about the product or here to receive a personalized quote.

The automatic hydraulic application of pre-set consolidation steps, up to 50, significantly enhances the functionality of the Shearmatic 300 – Large Shear Testing Machine by allowing precise and automated control over the consolidation process during testing. This feature enables users to program specific consolidation forces to be applied to the sample in sequential steps, simulating different environmental and loading conditions without manual intervention.

This level of automation ensures that each consolidation step is applied uniformly and accurately, providing consistent test conditions and reliable data. The ability to pre-set up to 50 consolidation steps allows for complex testing scenarios, including those that mimic natural soil settlement processes over time or the gradual application of load to engineering structures.

Such functionality is invaluable in geotechnical, environmental, and civil engineering research and testing. Understanding materials' behavior under different consolidation conditions is crucial for predicting their performance in real-world applications.

Click here to learn more about the product or here to receive a personalized quote.

The automatic test management feature in the Shearmatic 300 – Large Shear Testing Machine, which oversees the process from consolidation to failure, significantly improves the testing process by streamlining operations and minimizing manual intervention. With this feature, the operator's role is simplified to remove the clamping screws from the shear box, as the machine automatically controls the entire test sequence.

This automation ensures a smooth transition between the consolidation phase and the shear testing phase, leading to a more efficient and error-free operation. It allows precise control over test conditions, maintaining consistency across tests and improving results reliability. Automation of these critical stages reduces the potential for human error and ensures that testing parameters are accurately maintained throughout the process.

By automating test management from consolidation to failure, the Shearmatic 300 allows operators to focus on other tasks, increasing productivity and efficiency in the laboratory.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine features a straight connection between the shear box, drive unit, and load cell. This connection is designed for the axial transmission of horizontal force along the shear plane. This direct connection method improves test accuracy by ensuring that the force applied during the shear test is transmitted more uniformly and directly to the sample. Unlike the classic "swan neck" design, which can introduce angular discrepancies and potential force distribution issues, the straight connection minimizes any mechanical inefficiencies or distortions in force application.

This design enhances the precision of shear strength measurements by reducing the potential for external variables to impact the test results. It ensures that the data obtained reflects the true material properties, providing a more reliable basis for analyzing the shear strength and deformation characteristics of the tested materials. Such accuracy is crucial for engineering and construction applications, where understanding material behavior under shear stress is essential for ensuring structure safety and stability. The Shearmatic 300's innovative connection design underscores its capability as a state-of-the-art tool for advanced material testing.

Click here to learn more about the product or here to receive a personalized quote.

The large digital graphic display on the Shearmatic 300 – Large Shear Testing Machine significantly simplifies setting up test parameters, offering an intuitive and user-friendly interface. This display allows for easy navigation and immediate input of the desired test conditions, including speed, load, and displacement settings, among others. The visual representation of parameters and real-time feedback ensures that operators can quickly and accurately configure the machine for specific tests, reducing setup time and errors.

It is particularly beneficial for laboratory environments, where a variety of tests must be conducted under a variety of different conditions, to use this feature. As a result of the clear, graphical interface, the transition between tests is streamlined, which enhances operational efficiency and productivity. Furthermore, the ability to easily adjust and monitor the test settings on a large display makes it a lot easier for the testing process to be done more efficiently and accurately.

Click here to learn more about the product or here to receive a personalized quote.

The ability to set different speeds and travel directions (forward and reverse) for residual shear tests on the Shearmatic 300 – Large Shear Testing Machine provides significant advantages in testing flexibility and accuracy. This feature allows for a more comprehensive evaluation of the material's shear strength characteristics under various conditions, closely simulating real-world scenarios where materials may experience different stress and strain rates.

By adjusting the speed and direction of the shear, researchers can investigate the residual strength of soils or other materials, which is critical for understanding how these materials behave once they have undergone initial shear failure. This is particularly important in the study of landslide mechanics, soil stability under cyclic loading, and the long-term durability of geosynthetic interfaces.

Furthermore, the capability to customize test parameters to such a degree enhances the machine's utility across a wide range of applications. These applications range from academic research to practical engineering assessments. It allows for the precise replication of conditions necessary for specific standards or research objectives, thus making it relevant and reliable.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine's ability to apply every single step of axial force either instantaneously or through a linear ramp within a pre-set time interval significantly enhances its testing capabilities by providing a more nuanced approach to simulating real-world loading conditions. This feature allows operators to closely mimic the gradual increase or sudden application of stress materials might experience in their actual use environment. This allows it to better understand materials' behavior under a variety of conditions.

Applying axial force via a linear ramp over a specified time interval enables the observation of how materials respond to gradually increasing loads, which is crucial for studies of creep, relaxation, and long-term durability under sustained stresses. Conversely, the option to apply force instantaneously is vital for assessing material responses to sudden loadings, such as impact or shock conditions, reflecting the dynamic challenges materials face in construction, geotechnical, and environmental applications.

Click here to learn more about the product or here to receive a personalized quote.

Independent data recording for consolidation and failure in the Shearmatic 300 – Large Shear Testing Machine offers significant benefits for the analysis and understanding of material behavior under different testing phases. This feature allows for the precise separation of data collected during the consolidation phase from that collected during the failure phase of a test.

By differentiating between these two critical stages, users can gain a more detailed insight into the material's properties. They can also gain insight into how it responds to pre-loading conditions as well as to the ultimate shear stress leading to failure. This distinction is crucial for accurately assessing the material's structural integrity and resilience, providing valuable information for design and safety considerations in engineering applications.

Furthermore, independent recording enhances data analysis quality, enabling researchers and engineers to perform more nuanced evaluations of material performance. It facilitates a clearer understanding of the consolidation behavior of soils or other materials under load and their subsequent response to increased shear forces. This capability makes the Shearmatic 300 an essential tool for advanced geotechnical investigation, research, and development.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 - Large Shear Testing Machine supports data downloading via an RS 232 serial port with different protocols significantly benefits users by offering flexibility in data management and compatibility with various computing environments. This feature ensures that data collected during tests can be easily transferred to computers for detailed analysis.

By accommodating different data communication protocols, the Shearmatic 300 ensures seamless integration with a wide range of data analysis tools and engineering software, facilitating a streamlined workflow from testing to analysis. This compatibility is crucial for laboratories and research facilities that use diverse analytical methodologies. They require the ability to customize data processing and reporting to meet specific project needs or standards.

Moreover, the use of a standard RS 232 serial port for data transfer ensures reliability and ease of use, allowing users to quickly connect the machine to computers without the need for specialized adapters or interfaces.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine offers versatile sample size capabilities, accommodating samples up to 300 mm. For tests requiring smaller specimens, its flexibility is further enhanced by the option to reduce the sample size to 150 mm using the NG-WF2304/1 150 mm sample insert. This adaptability allows users to conduct a wide range of tests on different materials and under various conditions, ensuring the machine's applicability to multiple testing applications.

The ability to adjust sample sizes is particularly beneficial in geotechnical, environmental, and materials engineering, where the representativeness of the sample can significantly influence test results' accuracy and reliability. By providing options for both large and reduced sample sizes, the Shearmatic 300 meets the diverse needs of research and testing laboratories, making it a highly valuable tool for assessing the mechanical properties of soils, geosynthetics, and other construction materials. The availability of accessories like the 150 mm sample insert further underscores the machine's versatility and commitment to supporting comprehensive material testing.

Click here to learn more about the product or here to receive a personalized quote.

The 100 kN shear and vertical force capacity of the Shearmatic 300 – Large Shear Testing Machine is significant as it denotes the machine's ability to apply a substantial amount of force in both shear and vertical directions. This high-capacity feature enables the Shearmatic 300 to conduct rigorous testing on a wide variety of materials, including soils, geosynthetics, and construction materials, to assess their strength and deformation under large loads.

The capacity to exert up to 100 kN of force is particularly crucial for simulating real-world conditions where materials are subjected to high stress and strain, providing engineers and researchers with valuable data on material behavior and performance. This capability ensures the Shearmatic 300 can be used for advanced testing applications, such as evaluating the stability of earth structures, the integrity of foundation materials, and the durability of geosynthetic barriers.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine offers a maximum travel distance of 75 mm. This feature indicates the extent of movement that the machine can provide during a test, allowing for significant displacements to be applied to the sample. The 75 mm travel distance is particularly beneficial for conducting comprehensive shear tests, where the ability to observe the material's behavior over a wide range of displacements is crucial for accurately determining its shear strength and deformation properties.

This capability ensures that the Shearmatic 300 can accommodate a variety of testing situations. These cases range from assessing geosynthetic resilience under prolonged stress to evaluating soil and other construction materials' stability under shear forces. The ample travel distance enhances the machine's versatility, making it suitable for advanced research and quality control applications in the geotechnical, environmental, and civil engineering fields.

Click here to learn more about the product or here to receive a personalized quote.

The 2000W power rating of the Shearmatic 300 – Large Shear Testing Machine indicates its robust operational capacity. This highlights the machine's ability to perform intensive tests without compromise. This substantial power rating ensures that the Shearmatic 300 has sufficient energy to drive its mechanisms smoothly and efficiently, even under the full load of its 100 kN shear and vertical force capacity.

A high power rating is crucial for maintaining consistent performance during demanding tests, such as those requiring the application of high forces or the execution of tests over extended periods. It enables the machine to handle a wide range of materials and testing protocols, from soils and geosynthetics to other construction materials, providing reliable and accurate results.

Furthermore, the 2000W power rating supports the machine's various features, including its ability to apply different speeds and travel directions, manage up to 50 steps of consolidation, and sustain its maximum travel capacity.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine boasts overall dimensions of 147 cm in length, 76 cm in width, and 157 cm in height, translating to approximately 57.9 inches by 29.9 inches by 61.8 inches in imperial units. These substantial dimensions underscore the machine's robust design and capacity to accommodate many testing needs. These cases include those requiring large sample sizes or significant forces.

Machine size is critical, ensuring stability and durability during operation. It is designed to withstand intensive use in testing soils, geosynthetics, and construction aggregates under various conditions. The generous dimensions also facilitate the inclusion of advanced features, such as the capability for up to 50 steps of consolidation and the application of 100 kN shear and vertical force, enhancing the machine's versatility and making it a comprehensive solution for material testing.

Click here to learn more about the product or here to receive a personalized quote.

The Shearmatic 300 – Large Shear Testing Machine has an approximate weight of 800 kilograms (kg), which is roughly equivalent to 1763.7 pounds (lbs). This significant weight is indicative of the machine's robust construction and the use of heavy-duty materials designed to ensure stability and durability during testing. The substantial mass of the Shearmatic 300 plays a crucial role in its functionality, providing a stable base that minimizes vibrations and movements that could compromise test results' accuracy and reliability.

Furthermore, the weight reflects the machine's capacity to handle high-force testing scenarios, including those requiring up to 100 kN of shear and vertical force. It is equipped to accommodate large sample sizes and perform a variety of tests, from soil and geosynthetic testing to evaluations involving large particles. Despite its considerable weight, the Shearmatic 300 facilitates ease of installation and adaptability to different laboratory environments.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

Moisture Determination Balance - GenMoist

GenMoist is designed to automatically and simultaneously dry and weight a solid sample for the determination of moisture content. The machine provides a continuous direct readout for both the weight and the percentage moisture loss through the entire cycle. It has a build-in timer.

MULTISPEED Digital Automatic Universal Tester for Displacement Controlled Tests

The new MULTISPEED tester is the ideal solution for Road testing laboratory. The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not only the CBR and Marshall tests, but many other applications as for instance Indirect Tensile test, Quick Triaxial tests, Unconfined and Uniaxial soil testing and, in general, all test to be performed under displacement control. The machine can be equipped with analogical or digital load/displacement measurement systems as well as with the specific accessories, to suit either the field or central laboratory requirement.

Dynamic Triaxial Systems 1000 kPa

Dynatriax systems are ideal for commercial and research laboratories for the following applications: Liquefaction potential, Strength degradation due to cyclic loading, Shear modulus and damping ratio, resilient modulus, Effects of blasting in mines and quarries, Effect of ocean waves on costal and off shore structures.

Automatic Triaxial Test Systems

The AUTOTRIAX Automatic triaxial system not only can perform Effective Stress triaxial tests with all the above vantages but is the unique and indispensable apparatus to perform the Stress Path test.

NG-Oedometer - Front Loading Oedometers - Consolidation Test

This test determines the rate and magnitude of consolidation of a soil specimen restrained laterally and subjected to a number of successive increments of vertical loads.

ACE - Automatic Computerized Oedometer

ACE - is the most advanced automatic computerized oedometer for testing soil consolidation that can measure the response of soil specimens.

Resonant Column and Torsional Shear Tester

RESONANT COLUMN combines the features of both resonant column and torsional shear into a single unit including the current driven motor to apply torsional load to sample, a series of transducers with signal conditioning, a cell and back pressure electro-pneumatic control system and a data logger.

Automatic Shear Testing Machine

The microprocessor control system, therefore, allows the machine to work as an automatic stand-alone unit: the test measurements (force and displacements) a re directly displayed and stored in memory according to pre-set recording modes. The PC is only temporary required to download the test data via the RS 232 port once the test is completed. The data can be processed by the Direct and residual shear Geo-Analysis templates. See accessories.

Shearmatic - Automatic Shear Testing Machine

This microprocessor based advanced model, is a stand-alone machine, driven by a high-resolution stepper motor with epicyclical reduction gear with reduced backlash. Incorporate a pneumatic closed loop system for the automatic application of the axial pressure by a high performance pressure regulator, with the main advantage of eliminating the manual loading of the dead weights. Excellent and high resistance techno-polymeric material has been adopted for the carriage of the shear box. It offers excellent resistance to corrosion, wear and tear and is resistant to all chemicals found in a soil specimen. The carriage is lightweight and easy to clean.

Laboratory Vane Apparatus

The laboratory vane apparatus is based on an original concept of the Transport and Road Research Laboratory of the United Kingdom. It can be provided with a wide range of vane sizes, although as standard, it is sold with the 12.7 mm square vane and a set of four calibrated springs. The test can be performed directly on the sample or in the sample contained in the sampling tube. In this case the NG-WF1736 Attachment for 38 and 100 mm dia. sampling tubes, should be used. See accessories.