Soil Mechanics Testing Equipment

Standards

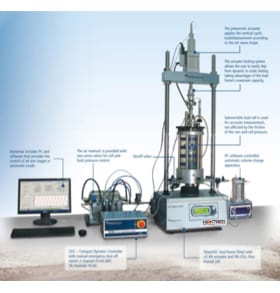

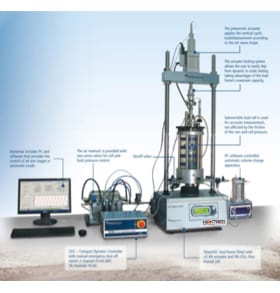

Description

Dynatriax systems are ideal for commercial and research laboratories for the following applications: Liquefaction potential, Strength degradation due to cyclic loading, Shear modulus and damping ratio, resilient modulus, Effects of blasting in mines and quarries, Effect of ocean waves on costal and off shore structures.

DYNATRIAX apparatus is a computer controlled servo-pneumatic systems, designed to perform the static and dynamic stages of a triaxial test. The systems manage three closed loop axis:

- Vertical load/displacement:

- -up to ± 25 mm (± 5 kN actuator)

- -up to ± 15 mm (± 14 kN actuator)

- Cell pressure up to 1000 kPa

- Back pressure up to 1000 kPa

The base systems include Tritech 50 or Tritech 100 Triaxial load frame, the Actuator, and the CDC Compact Dynamic Controller for data acquisition, control and processing. We propose three versions

- NG-WF7005 with 50 kN load frame and ±5 kN actuator

- NG-WF7006 with 50 kN load frame and ±14 kN actuator

- NG-WF7010 with 100 kN load frame and ±5 kN actuator

- NG-WF7015 with 100 kN load frame and ±14 kN actuator

New Dynatriax PID control

The DynaTriax has been upgraded with a new and improved PID control. A more efficient algorithm with larger gain ranges gives enhanced sensitivity, making it easier to tune the system and achieving a more accurate waveshape.

New features include manual and automatic amplitude controls which compensate for small changes that may occur in the system during cycling, ensuring that the required peak and valley levels are consistently maintained.

The improved tuning panel, with its more user-friendly interface, provides all the tools necessary to optimize system control during static and cyclic test stages.

Dynamic Triaxial Systems Main Features

FLEXIBILITY

- Three axis closed loop control for axial load or displacement, cell and back pressure

- Operating frequency up to 10 Hz

- Two dynamic load/displacement options:

- - Up to ±25 mm with ±5 kN actuator

- - Up to ±15 mm with ±14 kN actuator

- Capability to perform Static (effective stress and stress path), Dynamic and Unsaturated soil triaxial tests

- Available upgrade for Bender element testing and Local strain measurement

RELIABILITY

- Standard and user defined wave shapes also derived from in situ measurements (from violent earthquakes to sedate ocean waves)

- Complete test automation of all test stages using an high sensitivity closed loop P.I.D. feedback (up to 10 Hz)

- Automatic compensation of cell/back pressure during dynamic stage

- Transducer calibration and verification management by software

- Manual and automatic Emergency air shut-off function

MODULARITY

- Test set-up by unique programmable Multi stage test procedure: during the test run, access to all controls to expand and modify the stages according to the response of the soil specimen

- Designed to easily Integrate existing static systems

Dynamic Triaxial Systems Technical Specifications

Tritech 50 or Tritech 100 Triaxial load frames

The Tritech digital loading frames feature a microprocessor controlled drive system, specifically designed to perform both static and dynamic tests.

- Static load capacity: 50 or 100 kN

- Static vertical displacement: up to 100 mm (machine travel)

Actuators

The double acting pneumatic actuators are digitally controlled and includes an integrated LVDT displacement transducer to control the position and the displacement of the piston during the test.

- Dynamic load capacity: ±5 kN or ±14 kN

- Dynamic vertical displacement ±25 or ±15 mm

- Operating frequency: up to 10 Hz (depending on test conditions)

- Maximum servo-valve frequency: 70 Hz

- Min. air supply: 800 kPa

CDC Compact Dynamic Controller

The unit manages the three closed loop axis (vertical load/displacement, cell and back pressure) with a control loop rate of 10 Hz. It provides the automatic control of the system and drives the servo-valve units of the three axis and two on/off valves, one connected to the drainage line and one connected to the air main supply of the triaxial cell. The CDC communicates with the PC through an Ethernet communication link (1 Gbit/s). The CDC has sixteen transducer input channels using 16 bit ADC.

Software

Multitasking, user-friendly Windows-based software is pre-installed on the computer provided with the system. The software provides control of the following utilities and stages of a cyclic triaxial test:

- Saturation

- Cell pressure increments with B value check

- Back pressure increments with volume change measurement

- Cell and back pressure ramp

- Consolidation

- Isotropic consolidation with continuous volume change measurement

- Ko consolidation

Vertical displacement loading with sample diameter control using either:

- Direct measurement by radial belt with on-sample transducers

- Measurement of sample volume change and height

- Stress path

- Horizontal and Vertical Stress

- s, t (average stress and shear stress)

- p, q (mean normal stress and deviator stress)

- Vertical stress using strain control

- Monotonic shear

- Strain controlled static shear stage, drained or undrained

- Loading in compression or extension, using the vertical actuator or the Tritech

Any or all of the above stages can be performed in "Automatic mode" where the test parameters are entered at the start of the test or stage and the software takes control of managing the stages using predefined criteria.

- Cyclic loading

- ASTM D5311 Load Controlled Cyclic Strength

- ASTM D3999 Load Controlled Modulus & Damping

- ASTM D3999 Displacement Controlled Modulus & Damping

- Non Standard Single or multi cycle test

- User defined or imported Waveshape

- Transducer limits

- An air shut-off valve can be programmed to be activated using defined channel limits

- Calibration

- Digital calibration using linear fit, polynomial fit or linearization

- Transducer verification option

Related Products

Moisture Determination Balance - GenMoist

GenMoist is designed to automatically and simultaneously dry and weight a solid sample for the determination of moisture content. The machine provides a continuous direct readout for both the weight and the percentage moisture loss through the entire cycle. It has a build-in timer.

MULTISPEED Digital Automatic Universal Tester for Displacement Controlled Tests

The new MULTISPEED tester is the ideal solution for Road testing laboratory. The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not only the CBR and Marshall tests, but many other applications as for instance Indirect Tensile test, Quick Triaxial tests, Unconfined and Uniaxial soil testing and, in general, all test to be performed under displacement control. The machine can be equipped with analogical or digital load/displacement measurement systems as well as with the specific accessories, to suit either the field or central laboratory requirement.

Automatic Triaxial Test Systems

The AUTOTRIAX Automatic triaxial system not only can perform Effective Stress triaxial tests with all the above vantages but is the unique and indispensable apparatus to perform the Stress Path test.

NG-Oedometer - Front Loading Oedometers - Consolidation Test

This test determines the rate and magnitude of consolidation of a soil specimen restrained laterally and subjected to a number of successive increments of vertical loads.

ACE - Automatic Computerized Oedometer

ACE - is the most advanced automatic computerized oedometer for testing soil consolidation that can measure the response of soil specimens.

Shearmatic 300 - Large Shear Testing Machine

The SHEARMATIC 300 automatic machine is ideal for testing geosyntetics and also soil and other materials that contain large particles of up to 20 mm largest dimension. Sample size up to 300 mm square can be tested, with inserts allowing the testing of smaller sample sizes. See accessories.

Resonant Column and Torsional Shear Tester

RESONANT COLUMN combines the features of both resonant column and torsional shear into a single unit including the current driven motor to apply torsional load to sample, a series of transducers with signal conditioning, a cell and back pressure electro-pneumatic control system and a data logger.

Automatic Shear Testing Machine

The microprocessor control system, therefore, allows the machine to work as an automatic stand-alone unit: the test measurements (force and displacements) a re directly displayed and stored in memory according to pre-set recording modes. The PC is only temporary required to download the test data via the RS 232 port once the test is completed. The data can be processed by the Direct and residual shear Geo-Analysis templates. See accessories.

Shearmatic - Automatic Shear Testing Machine

This microprocessor based advanced model, is a stand-alone machine, driven by a high-resolution stepper motor with epicyclical reduction gear with reduced backlash. Incorporate a pneumatic closed loop system for the automatic application of the axial pressure by a high performance pressure regulator, with the main advantage of eliminating the manual loading of the dead weights. Excellent and high resistance techno-polymeric material has been adopted for the carriage of the shear box. It offers excellent resistance to corrosion, wear and tear and is resistant to all chemicals found in a soil specimen. The carriage is lightweight and easy to clean.

Laboratory Vane Apparatus

The laboratory vane apparatus is based on an original concept of the Transport and Road Research Laboratory of the United Kingdom. It can be provided with a wide range of vane sizes, although as standard, it is sold with the 12.7 mm square vane and a set of four calibrated springs. The test can be performed directly on the sample or in the sample contained in the sampling tube. In this case the NG-WF1736 Attachment for 38 and 100 mm dia. sampling tubes, should be used. See accessories.