Rubber Testing Equipment

Standards

ASTM D5963, EN ISO 20344, ISO 4649, DIN 53516, SATRA METHOD 174

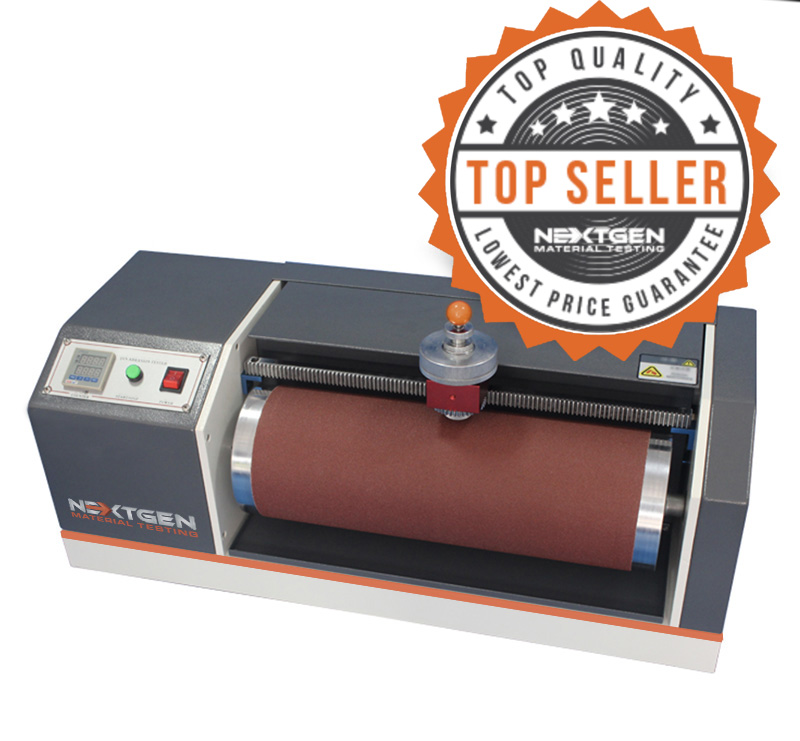

Certified DIN Abrasion Tester

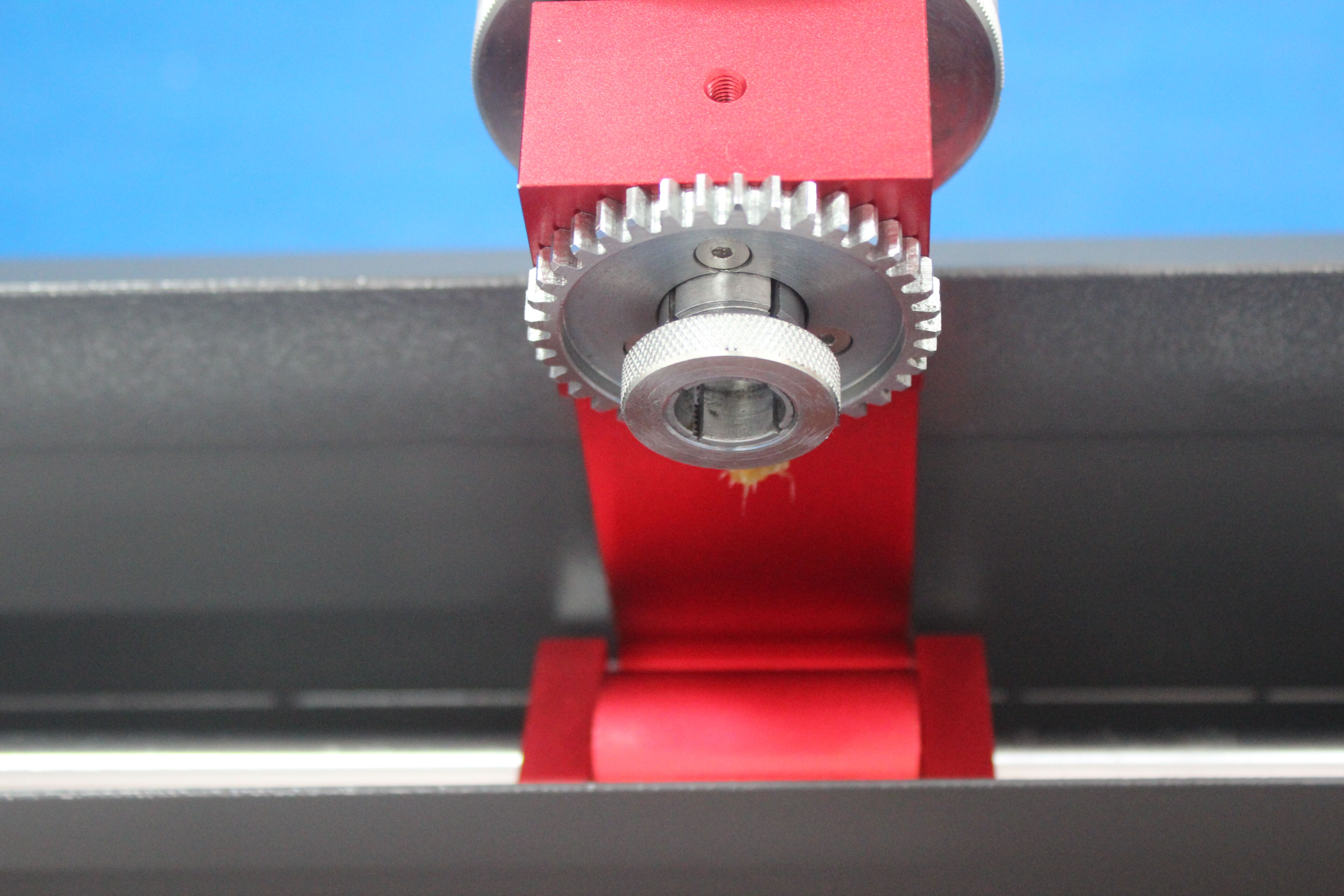

GenDin is designed to conform to the ASTM, EN, IS0 and DIN standards. This top quality and highly popular abrasion tester will allow you to measure the abrasion resistance of rubbers (vulcanized thermo set rubbers and thermoplastic elastomers) that are subject to abrasive/frictional wear on their actual service. Since wear is always a result of abrasion, different test methods have been developed for the simulation of long-term wear.

DIN Abrasion Testing Operation

DIN Method according to ISO 4649 Method 1 (without specimen rotation)

Certified DIN Abrasion Tester Supplier

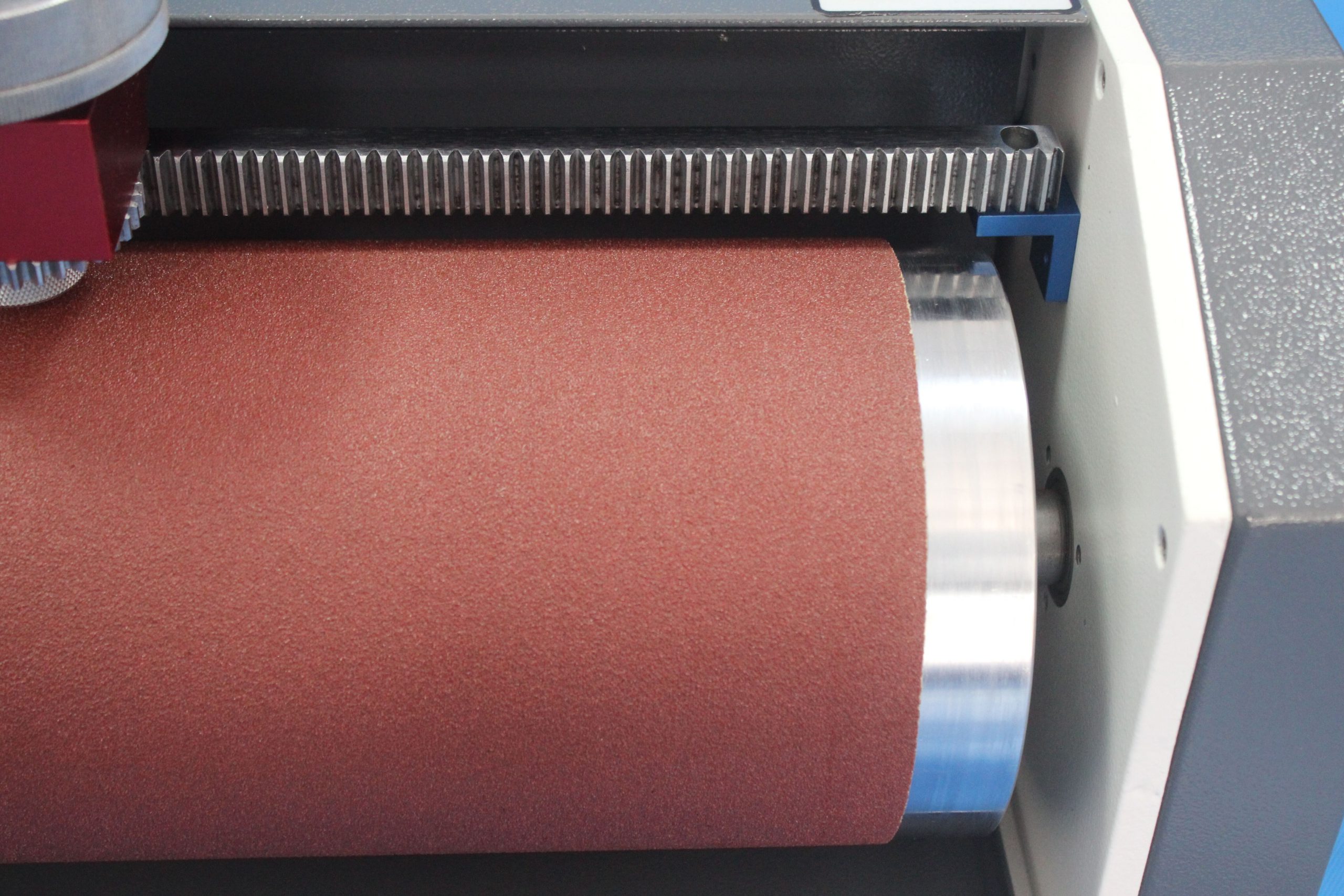

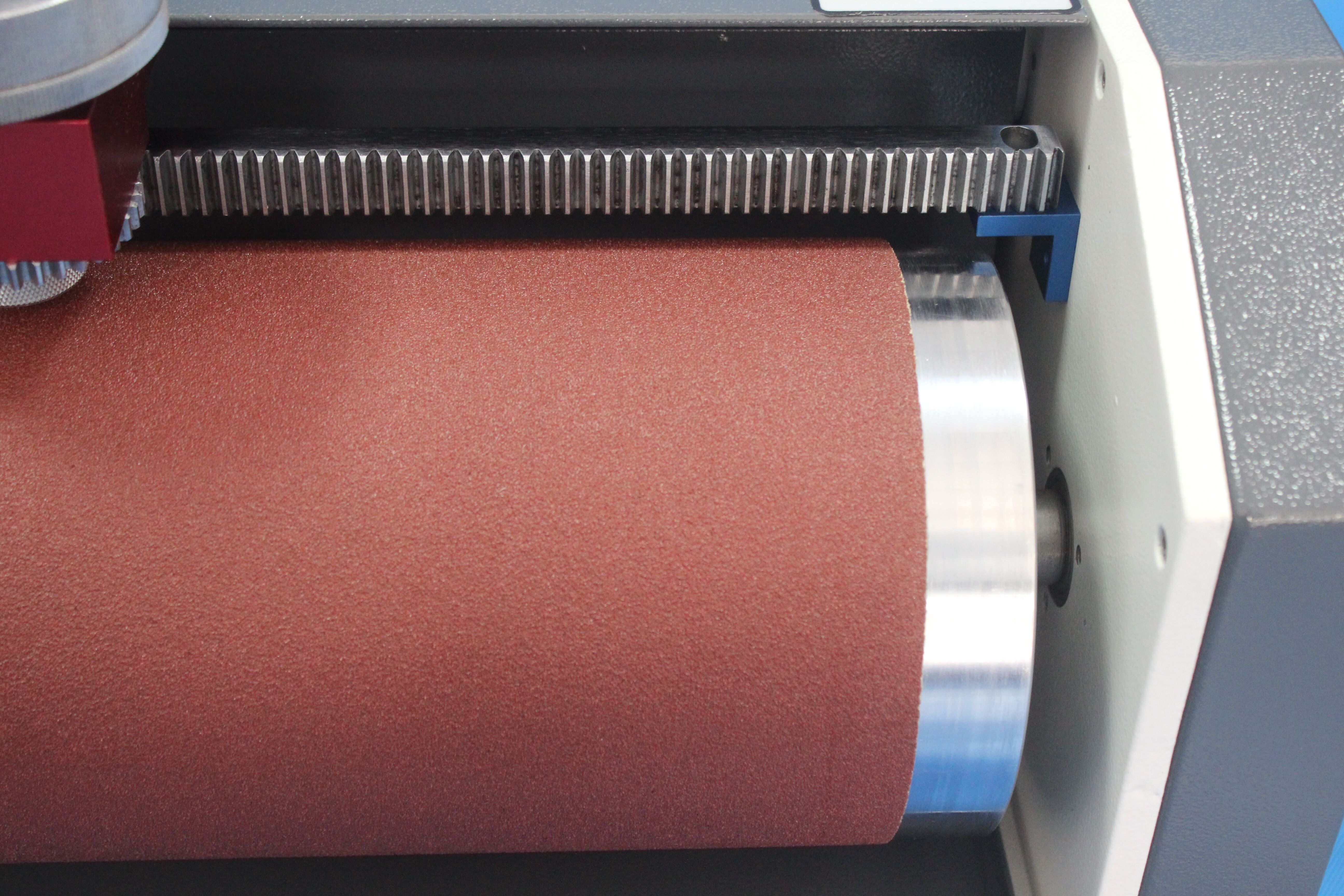

The method conforming to ASTM D5963 / ISO 4649 has proven to be the best way of simulating long term wear. This method enables comparative tests for the control of the uniformity of a specific material. The achieved test results provide important parameters with respect to the wear of elastomers in practical use. The abrasion resistance is measured by moving a test piece across the surface of an abrasive sheet mounted to a revolving drum, and is expressed as volume loss in cubic millimeters or abrasion resistance index in a percentage. Learn more about the significance of DIN Abrasion Testing.

Specifications

| Model | GenDIN |

|---|---|

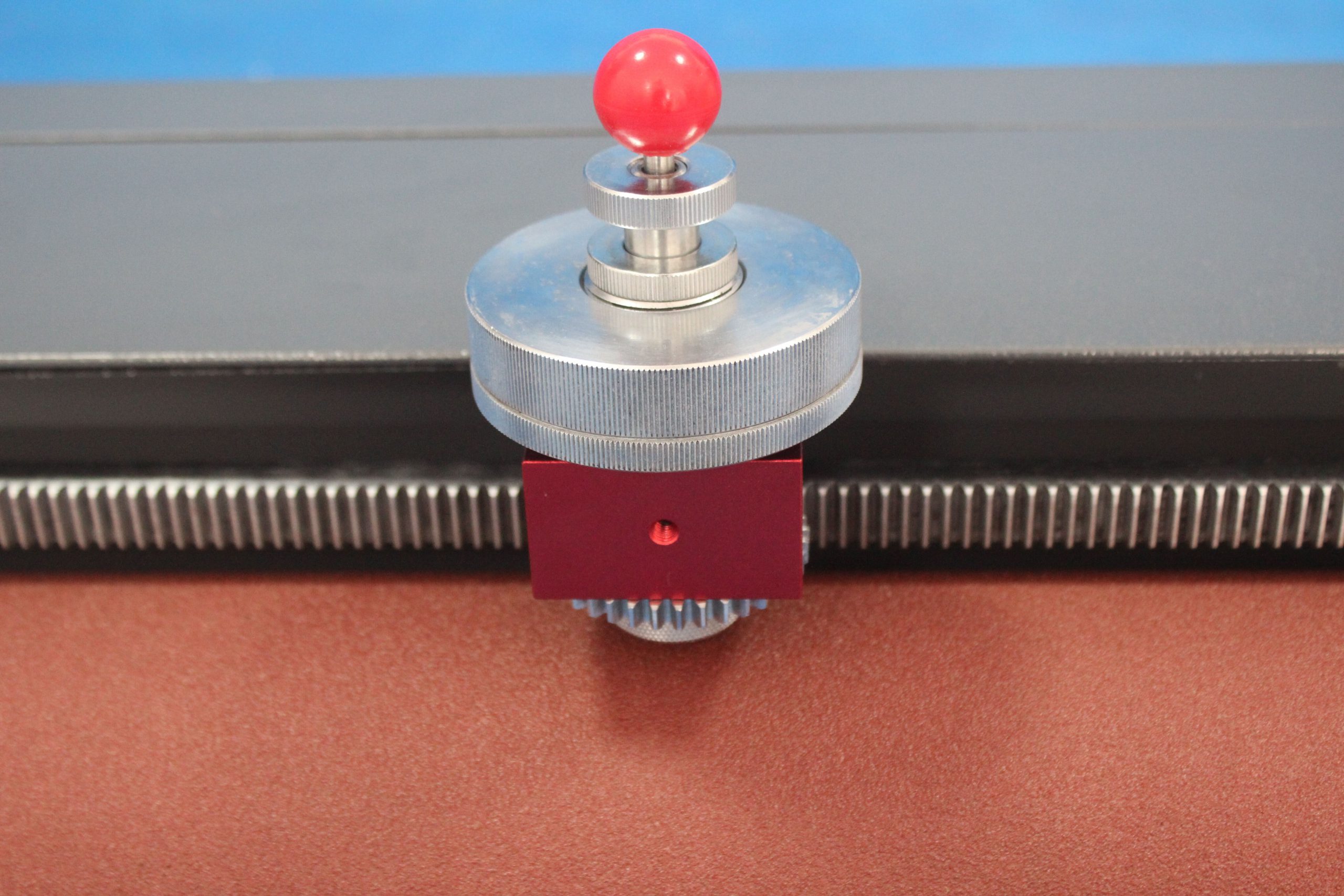

| Load | 2.5±0.1N; 5±0.1N; 10.0±0.2N |

| Specimen Size | Diameter 16mm, thickness 6-16mm |

| Rotating Drum Diameter | 150mm |

| Rotating Drum Speed | 40 ±1RPM |

| Emery Cloth Specification | 60 #, 425 ±473 ±1.5 (mm) |

| Testing Length | 40M (about 84 rotations) |

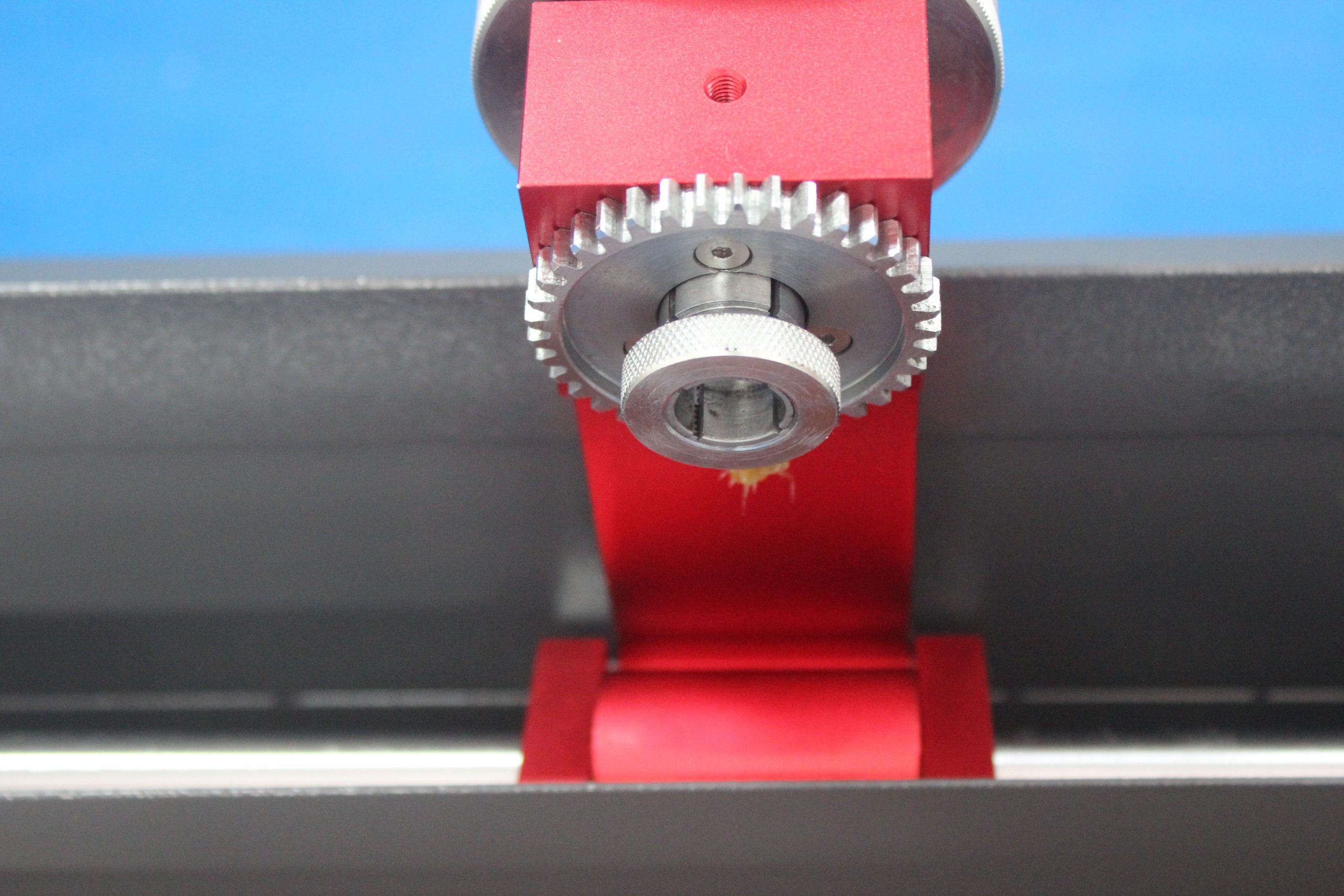

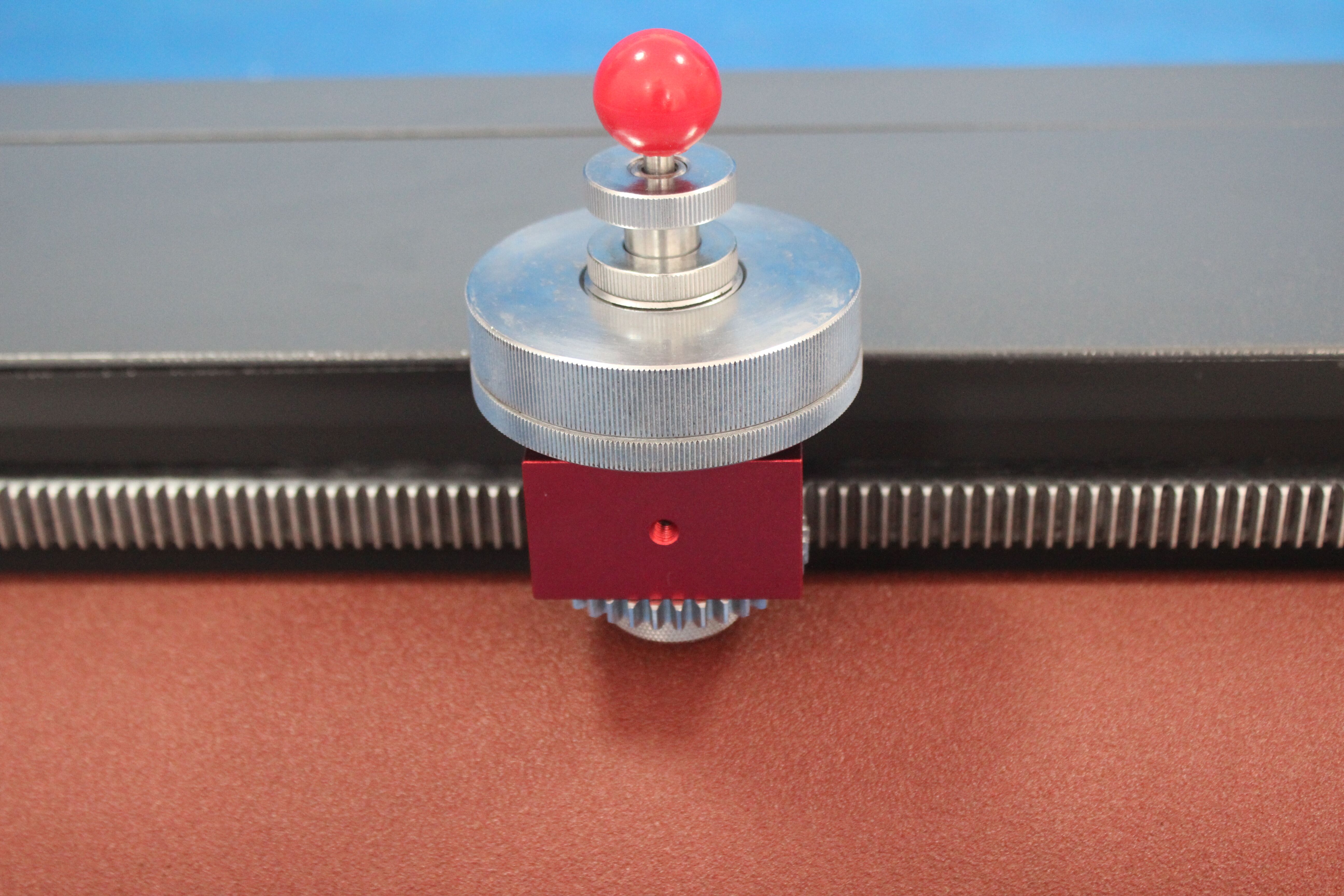

| Horizontal Displacement | 4.2mm / rotation |

| Test-Arm Weight | 250 ± 5 (g) |

| Shift Screw | 6 teeth / inch |

| Limit Rotation | 85 rotations |

| Set Rotation | 84 Rotations (about 40M) |

| Return Form | Automatic Electric Reset |

| Power | 110V/60Hz or 220V/50Hz |

| Machine Dimensions (W x D x H) | 70 x 30 x 30 (cm) 27.55 x 11.80 x 11.80 – inches |

| Machine Weight | 61 kg / 134 lbs |

DIN Abrasion Tester Consumables

GenDIN can be purchased with a full scope of DIN Abrasion consumables for your current and long-term needs. The consumables include abrasive paper, circular cutting device, standard rubber slabs, additional 10N loading weights and more. You purchase your DIN consumables with or after the order of the main instrument. Additionally, NextGen often offers special consumables bonus incentives. Ask us for our best consumables offer by request quotation today.

FAQs

A wide variety of industries use DIN abrasion methods for testing their products. These include the following industries and sectors: leather, textile, clothing, automotive, rubber, aerospace, rubber rollers, bearings and seals, R & D facilities, and rubber and plastic manufacturers, among many others.

Typically, these industries break into sub-industries that range from small, medium, to large-sized companies. Many of them use the DIN abrasion testing methods on a consistent basis as part of their quality control measures.

Depending on the application, the results of DIN abrasion testing are quite useful. In particular these are beneficial to manufacturers and designers of rubber products. Rubber abrasion tests are good indicators of the performance and quality of the material.

For designers, the data culled from the results can provide much help in their research efforts. Likewise, they can use the information for checking for the efficiency of the product. On the other hand, manufacturers can make use of the results to help develop better and higher quality products. finally, end-users get the assurance that the products they will use are made from superior and high quality materials.

Three test pieces are cut from various positions of the material with a diameter of about 16 mm with a + or - 0.2 mm allowance and thickness of about 6.0 - 10 mm using a tubular drill.

The piece of test specimen must be parallel to the bottom and top. The round of flank must be vertical to either side, which is in the column's shape.

Note: if the test piece thickness is less than 6.0 mm, another rubber test piece with a hardness of 65 HA must be taken in a similar way, and sticks to the test piece using universal glue. This is to guarantee the thickness of a minimum of 6 mm.

The number of test pieces must be at least 3 pieces taken from each type of material. Instrumental correction: After testing for 10 times, the instrument must be corrected using a standard rubber. It should be done in accordance to the following:

First, a standard rubber must be tested for three times. Its mean is indicated as S. The results are correct when the standard rubber wear mean is around 200 + or - 20 mg. If the results read more than 220 mg, it means that the sandpaper is too sharp and it needs to be readjusted.

Put the iron of the same size as the test specimen, then rub the rubber until it becomes less than 220 mg in size. If it achieves a size of under 180 mg after wearing, the sandpaper needs to be replaced because apparently, it is a bit too blunt.

Note: if the wears in the test piece have a variance of over 15 mg, then the specimen must be abandoned, and retesting must be done.

In general, these two methods of abrasion testing require similar specifications for the DIN abrader. However, the most obvious difference between the two is that ISO 4649 cites two methods for abrasion test - rotating or non-rotating. On the other hand, DIN 53516 doesn't have any clear requirements for the same. But, the two standards are capable of determining abrasion resistance in rubber.

Based on industry standards, the ideal sandpaper for use on the rotary drum is around 60#. The abrasive is rather coarse, and will result to a high volumetric loss.

When looking at the results of abrasion tests, it is very important to remember one thing: the higher figures are indications of a greater surface rubber loss. The higher the figure, the bigger the loss. This means that resistance to abrasion is lower. On the other hand, a lower figure is an indication of better resistance to wear.

A single belt that has good abrasion resistance can usually perform much longer and more efficiently than say, 2 or even 3 "economy" belts of lower grade or quality.

Following is the detailed procedure for DIN abrader testing.

- First, the abrasion sheet's abrasiveness is determined. Once it is done, the device is now ready for testing. The test samples can be drilled easily on the rubber sheet or the final product using the circular cutting knife, which is optional. Usually, the tests are done at an ambient temperature of 230 C + or - 50 C with the option to heat the drum at a higher temperature.

- The test specimen's weight is initially measured.

- The sample is next mounted onto the sample holder. Set the preferred abrasion distance and apply the load weights. The cover of the instrument is then put in place. The testing procedure commences by simply clicking on the tester's start button.

The drum will then begin to rotate, and the test specimen will be sent over the abrasion sheet. The moment the pre-determined abrasion distance is hit, the instrument will automatically stop running. - At the conclusion of the test run, the sample is taken out of the sample holder, then the weight of the test sample after the abrasion process is measured.

- Calculate the abrasion. To do this, convert the mass loss (with average value of 3 - 10 individual values) into volume loss with the aid of the density and the correction done for the abrasion sheet's abrasiveness deviation from the given value of abrasiveness.

The following formula is used:

Abrasion = mass loss x abrasiveness x 200 specific weight

Rubber is a very elastic and versatile material. It is the material of choice in production verticals because of the different properties it has. The material is used to manufacture industrial products, domestic products, toys, and accessories, among others.

Rubber comes from the rubber plant. However, the rubber material taken from plants is quite soft by nature, and is not suitable for use in industrial applications. It cannot be molded into different shapes and sizes. The rubber material is hardened through the vulcanization process.

This is where abrasion testing comes in. The produced rubber material is tested to make sure it is durable enough for use as a material for manufacturing various products.

Abrasion testing is performed on materials that abrade or wear off over time. Some examples of these materials are belts, tires, shoe soles, and conveyor belts, among others.

In a DIN abrasion test, the specimen is secured into a sample holder (quick clamp), and then guided in a precise manner, with or without rotation, over a predetermined distance of either 20 m or 40 m. There is also a given load on a piece of abrasive paper that is mounted to a 150 mm diameter stainless steel rotary drum. The drum turns at a speed of around 40 rpm. Ultimately, the frictional loss is computed by comparing the weight of the test specimen before and after the test.

The rotary drum-type DIN abrasion tester performs test in compliance with DIN ISO 4649, D53516, ASTM D 5963, and AS1683.21.

Related Products

Rotary Abrasion Tester Single & Dual Wheel

GenRotary used evaluate abrasion resistance. It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. The Joss of weight reflects on the change in weight of the specimen. The unit also has an intelligent power failure recovery function.

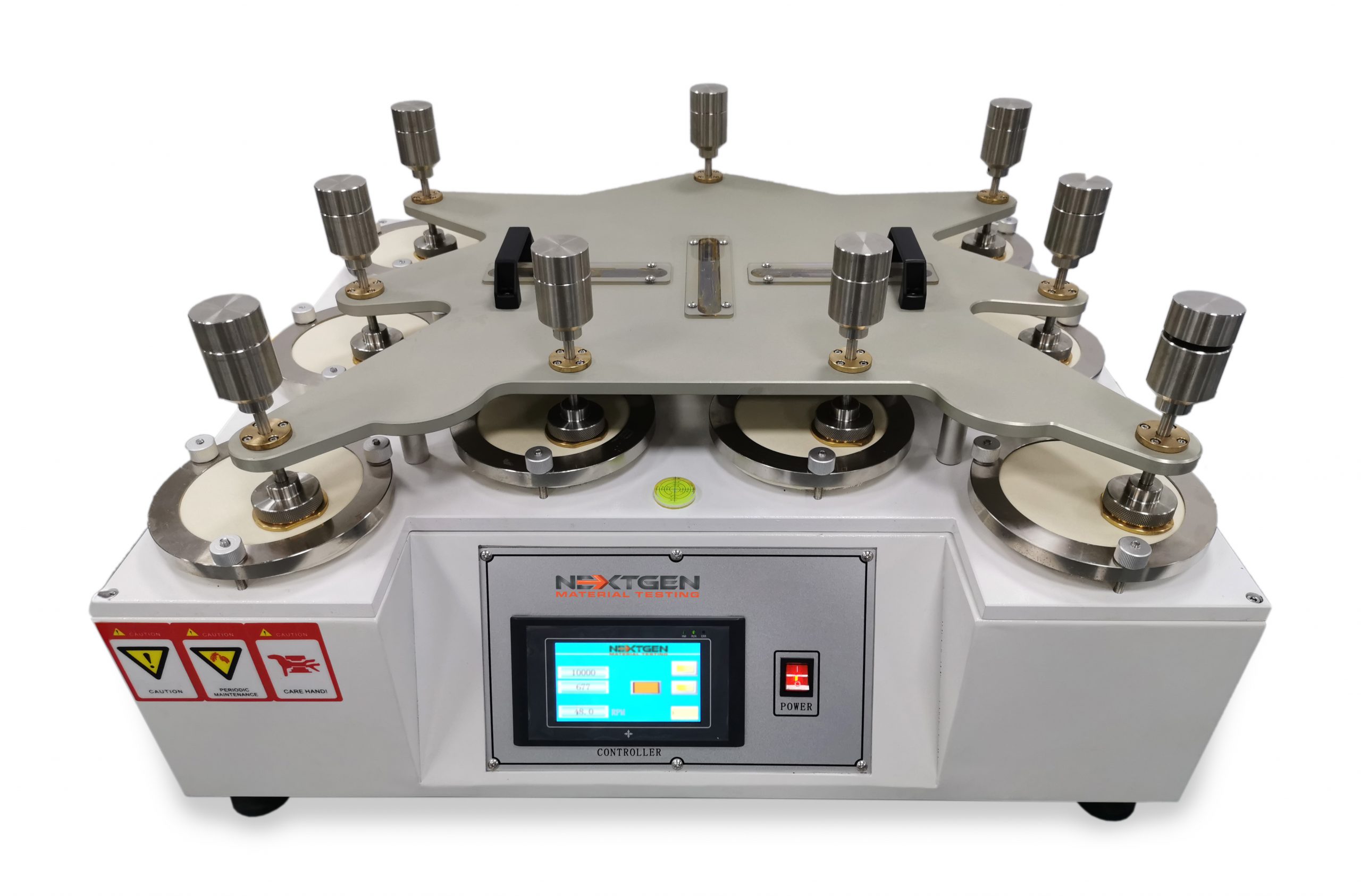

9-Station Martindale Abrasion Tester

The GenDale - Martindale Abrasion Tester is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials.

GenRoss-CH - Ross Flex Tester with Low Temperature Chamber

GenRoss-CH is an advanced Ross Flex Tester designed for assessing the cold resistance of materials in low temperature environments.

Linear Taber Abrasion Tester

NextGen's linear abrasion meters evaluate the abrasion and scratch resistance of products, along with color transmission.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

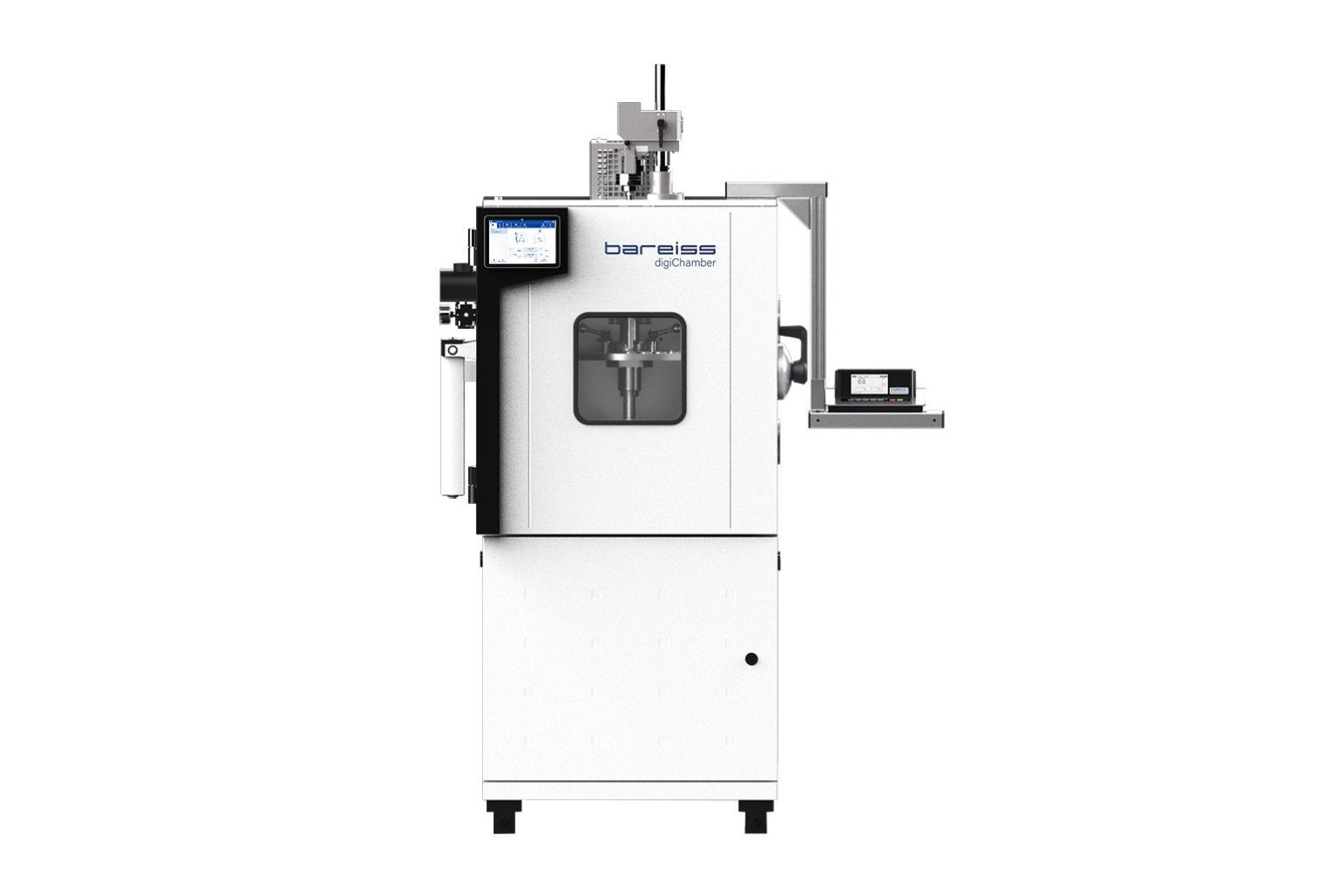

digiChamber - Temperature Controlled Hardness Testing

Discover digiChamber from NextGen Material Testing, the advanced temperature-controlled hardness tester developed by Bareiss.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

RPA Ultra - Advanced Rubber Process Analyzer Rheometer

RPA Ultra is an advanced rubber process analyzer rheometer that measures the dynamic and static characteristics of raw rubber compounds

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Akron Abrasion Tester

GenKron is used together with a special balance for testing the abrasive consumption of materials. The measurements are done through volumetric loss of a rotating specimen exposed to the action of a standard grinding wheel. It is especially suited for testing harder materials such as shoe soles, tires and other rubber materials.

Burst Strength Tester for Fabric

GenBurst is designed to test anti-rupture strength of variety of materials such as leather, paper and fabric. The unit tests the resistance of specimens to bursting using a hydraulic diaphragm bursting tester.

Demattia Flex Cracking Tester

GenFlex tests the ability of rubber products to withstand repeated flexing without developing cracks is of prime importance where such products are used in conditions undergoing repeated flexing. Flexing endurance of rubber products is determined by simulating in laboratory the action of flexing repeatedly under standard conditions of speed, mode, and degree of flexing.

Discoloration Meter

The machine is used to simulate an environment of sunlight radiation on a specimen to identify the resistance of fabric to discoloration.

Electric Crocking Tester - GenCrock

The machine is used to test the dyeing of the fabric, and the fade degree of the leather after dry or wet rubbing. The test method involves the specimen to be fastened to the base of the crocking meter and rubbed with an abrasive hammer attached to a wet or a dry cloth under controlled conditions. The transfer of colour is then measured using a scale to evaluate the rating of the specimen's dyeing grade.

Freezing Tester - GenFreeze

GenFreeze is specially designed to test the characteristics of various materials in a cold environment to ensure suitability for use in a cold climate. Based on the testing demand, adjust the beater and flexing grip, then load to the desired position. It can be used to test rubbers, leather, and plastics, PU leather etc. The unit can be adjusted to meet different requirements.

Martindale Abrasion Tester - GenDale

GenDale is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials. The unit can test up to four specimens at the same time for abrasion. The fabric specimen is measured by having rubbing applied on it via a complex direction of back and forth motion. The accuracy of abrasion strength is determined by the specific number of cycles conducted until a hole appears in the test area of the fabric specimen.

Mooney Viscosity Testing Machine - GenMooney

GenMooney is a viscosity testing machine is applied to measure the viscosity of the unmixed or mixed unvulcanized natural rubber, synthetic rubber and regenerated rubber .This tester has many functions such as fast warming, maintaining temperature, data stability, etc. It is equipped with an automated calibration feature for a simple data calibration of each experiment.

NBS Rubber Abrasion Tester - GenNBS

GenNBS is used to test the abrasion resistance of vulcanized rubber or other rubber compounds. It is commonly used for the soles and heels of footwear. It has an intelligent power failure recovery system. The unit conducts measurements through volumetric loss of specimens exposed to the action of a normalized abrasive medium secured to a rotations cylinder.

Oscillating / Automatic Disc Rheometer (ODR)

This machine is designed to get the characteristic curve and characteristic parameters of rubber vulcanization by measuring the applied moment of rubber to the oscillating dye body. NG-ODR rotor-free vulcameter has an excellent stability of results. The data and diagrams can be used as a reference for development, research and production quality.

Salt Spray Tester - GenSalt

GenSalt is designed to test the surface of different materials for resistance to corrosion. The unit is commonly used to test coated materials of a metallic nature in a controlled corrosive environment. The test can be used on rust-proof painting, anodizing, electroplating and rust-proof of grease. The machine imitates expedited corrosion process via salt spraying on a given test sample to identify the corrosion (oxides) resistance. Test results are based on the longevity of time a material can resist visible corrosion on the test sample.

Wyzenbeek Abrasion Tester - GenWyze

The machine is designed to test the abrasion resistance of fabrics and metals. The abrasion of fabrics is tested when the specimen is pulled over the frame and rubbed against an abradant over a curved surface. The number of cycles, also known as double rubs, conducted on the specimen before the fabric shows visible wear is used to determine the rating of abrasion.

Vertical Rebound Resilience Tester - GenRebound

GenRebound tests the resilience of rubber compounds. The machine must be adjusted in a horizontal position and the plunger raised at a specific height. The plunger is then released onto the specimen for a given number of impacts. The measurements are based on the 4th, 5th, and 6th impacts. The average of the three (3) measurements is then calculated for the test result. The machine is highly useful in production of compounds designed to absorb vibration or shock according to the ASTM standards.

Digital Densimeter Systems

Description The NG-DM-A Series offers high-accuracy digital Densimeters designed for a wide variety of material testing needs. These elegant and compact densimeter systems offer capacity ranges from 150g to 3000g with accuracy of 0.001g/cm3 down to 0.0002g/cm3. Advanced Densimeter System […]

Ross Flex Tester

Ross Flex Tester is designed to determine the resistance of vulcanized or synthetic elastomers to cut growth. The system does so under continuously bend flexing in 90°.