Metal Testing Equipment

Standards

ISO 18625, ASTM A956, JIS B7731

Description

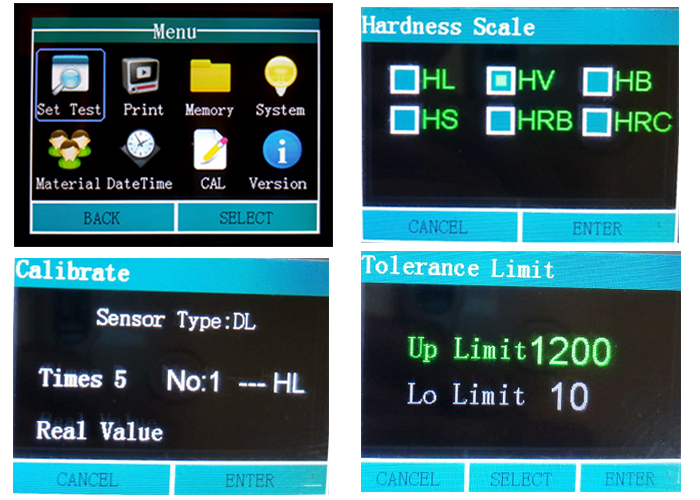

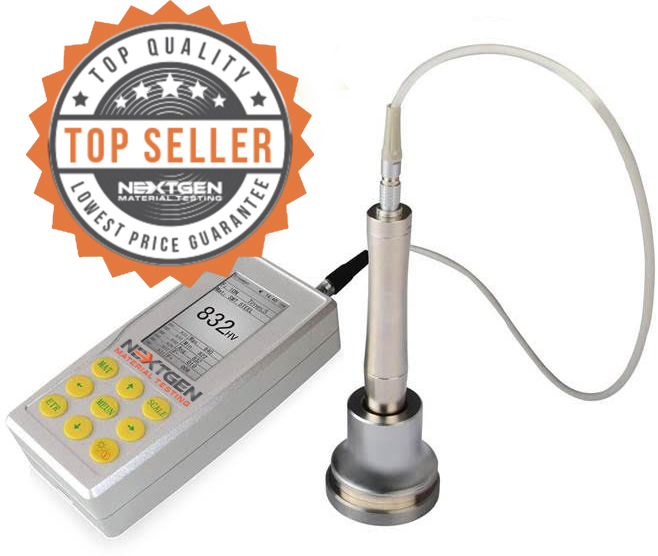

LeebGen3000- Leeb Portable Rebound Tester is a non-destructive precision metal hardness tester developed according to the latest industry standards. LeebGen 3000 is equipped with features which provide the instrument with a combination of a user-friendly interface and exceptional test result accuracy. This in turn allows for ease of operation and an accurate conversion display of virtually any metal hardness testing value.

The Leeb Portable Rebound Tester LeebGen 3000 is designed to replace the traditional stationary metal hardness testers, such as Vickers, Brinell and Rockwell. Its portable design allows to draw the most accurate test data regardless of the direction of the hardness test measurement. This is accomplished with a built-in 360° automatic angle adjustment system. LeebGen 3000 utilizes the latest in advanced micro-electronic technology, and provides you with a fast, convenient and a cost effective quality testing solution.

Main Function and Features of Leeb Rebound Portable Hardness Tester

- A large, high contrast LCD screen for premium image quality in any condition

- The unit is equipped with a self-contained Universal D Impact device which eliminates the need for cables. Additionally, the unit is equipped with an impact direction sensor.

- High testing result with precision within +/-4HL in any impact direction with 360° automatic angle adjustment.

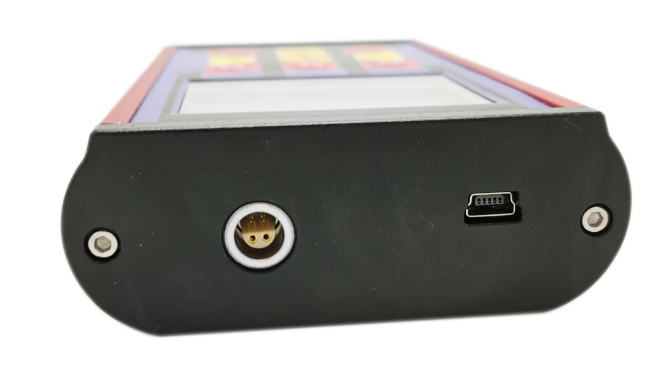

- Equipped with a USB port for ease of data transfer to a PC. Professional software is included at no extra cost.

- Internal data storage of dates and times of use

- Rechargeable battery through the USB port

- LeebGen 3000 has an integrated display of results for all common hardness scales including: Rockwell, Vickers, Knoop, Brinell, Shore and more.

- The unit comes standard with a wireless BlueTooth mini printer.

- LeebGen 3000 is designed for ease of calibration

- Equipped with an intelligent sleep mode

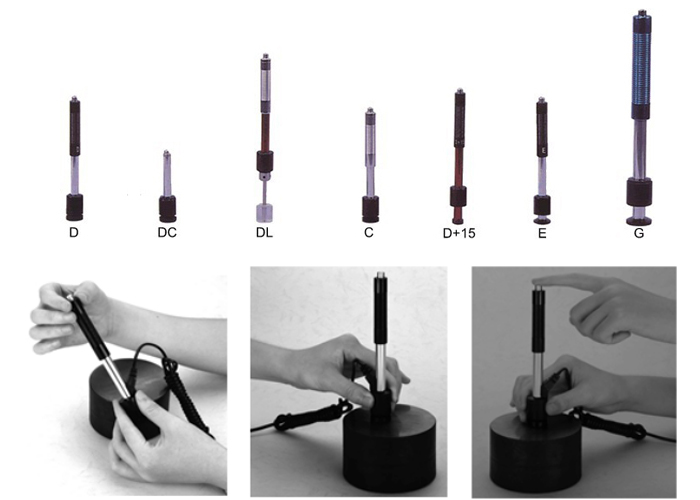

Impact Devices

| Impact Device | Image | Description | Commonly Tested Materials and Methods of Application |

|---|---|---|---|

| D |  |

Impact D is the universal unit for most hardness measurements. It is capable of a wide measuring range up to 68 HRC. | Steel and cast steel, cast iron, stainless steel, bronze, cast aluminum alloys, brass, wrought copper alloys and more. |

| DC |  |

Impact DC is designed for the harder to reach places. The device has similar properties and applications as the D, with testing components up to a maximum of 68 HRC. | Holes, cylinders, or measurements inside of an assembled machine and construction. |

| D+15 |  |

Impact D+15 is very similar to Impact D, the D+15 tests components up to a hardness of 68 HRC. Additionally, it has the same range of applications as the D and DC however has a different physical structure. The device is used with an elongated impact body and a coil which has a raised position of 0.6" or 15mm. | Holes and groves on a dipped surfaces |

| DL |  |

Impact DL can test a parts of up to a maximum of 68 HRC. The impact device has the same range of application as the D+15 with an exception of a more narrow front section. | Drill holes, gears and tight-to-reach spaces in the base of grooves. |

| G |  |

Impact G is designed with an increased impact energy of roughly 9X to that of the Impact D device. It can test materials of up to 646 HB. The larger diameter of the spherical tip allows for a more accurate measurement on a coarse microstructure. As a result, impact G does not need as much surface finish as the D device for an accurate readings. | Designed for rougher and heavier metals including: Cast aluminum, castings and forgings, cast iron, steel and cast steel. |

| C |  |

Impact C is equipped with a reduced impact energy. Relative to the Impact D, the energy impact is roughly 25% lower. The impact tests materials up to a maximum hardness value of 70 HRC. A better surface finish is required for Impact C then for Impact D. | Case hardness depth, coatings with a layer thickness of 0.1" or 0.3mm and impact sensitive materials requiring a small measuring indentation. Additionally uses: Cast steel, steel, cold work tool, and various cast aluminum alloys. |

* Different Impact Devices - imeko.org

LeebGen 3000 |

|

|---|---|

Operating Environment |

-10-+60°C; Humidity: 20%-85%. |

Storage Environment |

-30-+80°C; Humidity: 5%-95%. |

Dimensions (LxWxH) |

147x35x22 mm |

Weight |

100 g |

Measuring Range and Materials

Material |

HLD |

HRB |

HRC |

HB |

HV |

HSD |

|---|---|---|---|---|---|---|

Steel and cast steel |

300-900 | 39-100 | 20-68 | 81-654 | 81-955 | 32-100 |

Cold work tool steel |

300-840 | - | 20-67 | - | 80-898 | - |

Stainless steel |

300-800 | 46-101 | - | 85-655 | 85-802 | - |

Grey cast iron |

360-650 | - | - | 93-334 | - | - |

Nodular cast iron |

400-660 | - | - | 131-387 | - | - |

Cast aluminum alloys |

170-570 | 23-84 | - | 19-164 | - | - |

Brass |

200-550 | 13-95 | - | 40-173 | - | - |

Bronze |

300-700 | - | - | 60-290 | - | - |

Copper |

200-690 | - | - | 45-315 | - | - |

Related Products

Ultrasonic Contact Impedance Hardness Tester - UH200

Welcome to our most advanced and cost-effective Ultrasonic Hardness Testing System. This portable machine is all you need and more!

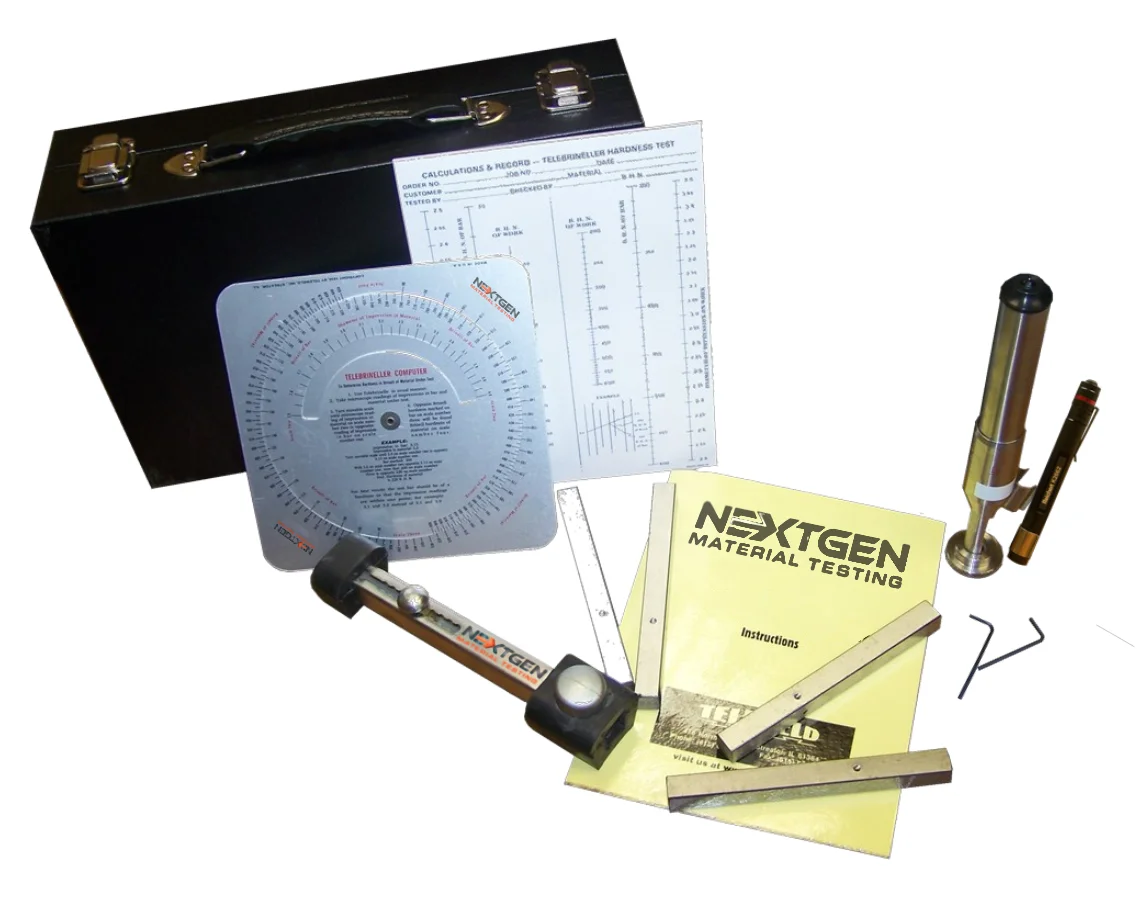

NextGen Telebrineller Brinell Hardness Testing System

The Telebrineller Brinell Hardness Testing System stands out as the best QA solution for ensuring top-notch quality. Developed specifically for welding crews, Telebrineller draws on over fifty years of field experience and solid metallurgical knowledge. Portable and practical, the entire Telebrineller system, housed in a case, weighs less than ten pounds. It's an ideal choice for Brinell hardness testing in any situation.

Surface Roughness Testers

High accuracy surface roughness testing systems for material surface analysis and statistical processing of data. Multiple model variations to help fit your technical and budgetary expectations.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.